WC–Co cermets are well-established as materials highly resistant to wear in a wide variety of situations; the main parameters influencing their properties are carbide grain size and volume fraction and binder mean free path. The abrasive wear resistance of sintered WC–Co cermets has been shown to increase dramatically as the carbide grain size is reduced . Recently, sintered nanoscale WC–Co w x cermets, i.e., materials which have nanoscale approxi- Ž mately 70 nm tungsten carbide WC grains in a cobalt . Ž. matrix, have been reported to exhibit enhanced performance in both sliding and abrasive wear 2–5 . They also w x benefit from substantially higher hardness than their conventional counterparts i.e., those which have carbide grain Ž sizes around the micron size upwards 6 . These property . w x improvements stem from the fact that as the carbide grainsize is decreased for a given cobalt content , the mean Ž . free path of the matrix is reduced, resulting in greater constraint and increased hardness. This results in less indentation of the cermet by the abrasive and less exposure of the soft and ductile matrix to the abrasive particles and hence, a generally more homogeneous, wear-resistant composite.

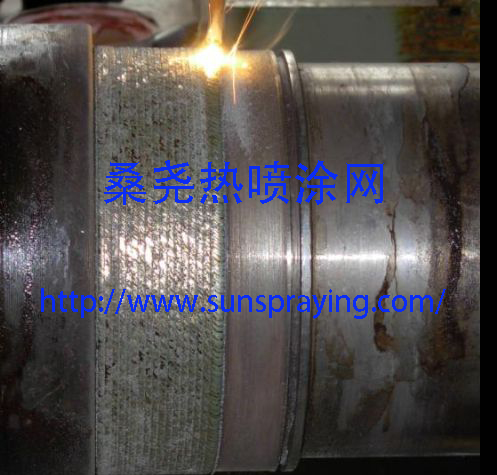

Thermally sprayed WC–Co coatings, of the order of 200–400 mm thick, are widely used in many industries as they offer an effective and economic method of conferring wear resistance without compromising other attributes of the component. High velocity oxy-fuel HVOF thermal Ž . spraying has shown itself to be one of the better methods for depositing conventional WC–Co feedstock powders w x 7–9 because the higher velocities and lower temperatures experienced by the powder particles as compared to plasma Ž based routes result in less decomposition of the WC . during spraying 10 . Consequently, this results in higher w x quality, more wear-resistant coatings, with higher levels of retained WC and less porosity. However, the effects of powder morphology, type of HVOF spray system and spray parameters have all been shown to affect the coating microstructure and, in turn, the wear resistance.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|