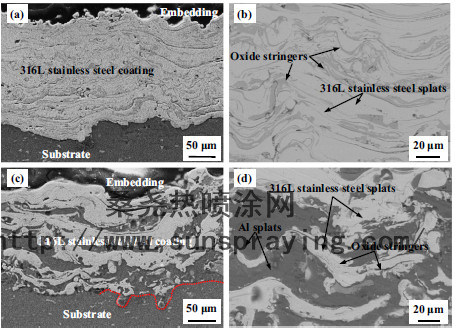

Al alloys have the advantages of high specific strength, light weight, excellent casting performance, good corrosion resistance, and low cost. They are widely used in the aerospace, transportation, and automotive industries. The disadvantages of using Al alloys as a wear material are low hardness, poor tribological properties, and serious adhesive wear. To improve the wear and friction of Al alloy surfaces, several studies have been carried out. First, an Al alloy of corrosion resistance and corrosive wear resistance were improved by micro-arc oxidation, and the wear and friction were improved by laser shock processing. A more effective way is that the multiphase coating prepared by plasma nitriding has better antifriction properties. The simple process is anodized technology, which effectively improves the wear resistance of Al alloy under dry friction reciprocate sliding. These technologies significantly improve the surface hardness, corrosion resistance, wear resistance and other properties of metals and their alloys. However, their resulting surface protective layers are very thin and have short wear lives. Further, ceramic coatings were prepared by plasma spraying and laser cladding, which exhibits excellent wear resistance and crack propagation resistance. However, due to the mismatch between metal and ceramic of thermodynamic and mechanical properties, the service life of ceramic coating is short. By preparing metal-ceramic coupling interfaces, metalceramic continuous gradient coatings and nanocomposite coatings, the shortcomings of metal-ceramic coatings cannot be completely overcome. To improve the wear resistance of aluminium alloys, an Al/316L stainless-steel composite coating was successfully prepared on an aluminium alloy surface by two-channel-synchronization wire feeding arc spraying technology. The composite coating has a ductile (Al) and hard (stainless-steel) interpenetration structure. The interface between the substrate and the coating was fuzzy owing to the pinning interface of interpenetrating structure and the obvious diffusion layer near the interface, compared with 316L stainless-steel coating. The tribological properties of composite coatings were analysed. The wear resistance of the Al/316L stainless-steel composite coating was shown to be three times higher than that of the stainless-steel coating. The Al/316L stainless-steel composite coatings improved the wear resistance of aluminium alloy by a factor greater than nine. In the composite coating, the addition of Al splats promoted the formation of Fe3O4 and the interpenetrating structures, improving the wear resistance and crack propagation resistance of the coating.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|