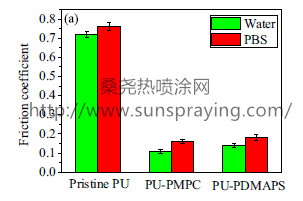

Polyurethane (PU) has been widely used as vascular grafts, heart valves and intravascular catheters because of the excellent mechanical property and good tissue compatibility compared to other synthetic polymers. Although PU is biocompatible, intense research is still going on in order to improve its surface antifouling property. So development of novel strategy for surface modification is necessary for a variety of applications in order to tailor the surface properties to the individual requirements while maintaining the bulk properties. Current surface functionalization methods include plasma and ozone treatments, deposition of self-assembled monolayers and engineered peptide-binding surfaces. Although these methods have been widely established in laboratory research, they display substrate dependent limitations in more widespread applications. Recently, polydopamine (PDA) based surface modification method inspired by marine mussels has been reported as a versatile surface modification technique that is effective irrespective of substrates. Compared to other surface modification technology, PDA basedmodification method was more convenient to achieve. In the present research, a versatile method for surface modification and functionalization of polymer substrates was provided. Firstly, polydopamine (PDA) was immobilized on PU surfaces. Then the hydroxyl and amine groups on the PDA coating reacted with azidoethyl carbon ylimidazole to introduce azido moieties, which provided the clickable groups to finally obtained surface. Zwitterionic polymer brushes were grafted on the azide-functionalized PU surface by onepot ATRP and click Chemistry. Finally the surface hydrophilicity, lubricating and antifouling properties were investigated. Poly(2-methacryloyloxyethyl phosphoryl choline) (PMPC) and poly(N,N′-dimethyl-(methyl methacryloyl ethyl) ammonium propane sulfonate) (PDMAPS) were grafted on polyurethane (PU) surfaces by one-pot ATRP and click chemistry in order to improve the lubricating and antifouling properties. The successful grafting of PMPC and PDMAPS was confirmed by X-ray photoelectron spectroscopy. The immobilization of zwitterionic polymer brushes significantly improved the surface hydrophilicity and lubricating property of PU. In addition, the protein and bacteria adsorption on the modified PU surfaces were reduced greatly due to the presence of hydrated layer around the zwitterionic groups. The present surface modification approach was simple and versatile for functionalization of polymer surfaces.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|