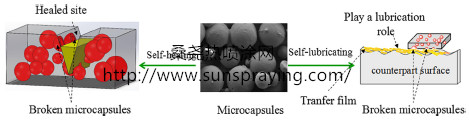

The fabrication of self-lubricating materials by incorporating lubricant-loaded microcapsules into a matrix has been reported widely. In the system of self-lubricating materials, a liquid lubri-cant is released to the surface as the solid matrix wears out, without the need for external intervention or maintenance. Thissignificantly decreases friction coefficients. Many relevant studies have been reported aimed at bulk polymer. Paraffin wax [22–25],lubricant oil [26–28], sulfureted fatty [29], and hexamethy lenedisocyanate (HDI) [30] have been microencapsulated and incor-porated into bulk polymers to prepared self-lubricating materials .The tribological tests showed effective reductions in friction coef-ficients and wear rates. Although there are few reports aboutpolymer-based self-lubricating coatings, Bandeira and co-workers studied the incorporation of microcapsules containing an ionicliquid lubricant in polytetrafluoroethylene (PTFE) coatings. Thetribology properties were evaluated [31]. Armada et al. incorpo-rated lubricant-loaded microcapsules into a nylon matrix by athermal spray process. The self-lubricating properties of coatings have been investigated [32]. Yang et al. prepared a polyure thaneself-lubricating coating by adding silica gel shell microcapsules containing an ionic liquid. The coating displayed a much lower fric-tion coefficient and less wear as compared to a coating with unfilled microcapsules [33]. Polysulfone microcapsules containing tung oil were synthesized by a solvent evaporation method. Themean diameter and wall thickness of the synthesized microcapsules were approximately 130 _m and9 _m, respectively. High thermal stability of the microcapsules with a thermal degradation onset tem-perature of 350◦C was obtained. The multi-functional coating was fabricated by incorporating themicrocapsules containing tung oil into an epoxy matrix. The self-healing and self-lubricating functions were evaluated by corrosion and tribology test. 10 wt% microcapsules embedded in epoxy coating offeredoptimum results. The microcapsules showed excellent anticorrosion performance in scratched coatings,which was attributed to the formation of a cross-linked polymer film after tung oil was released from the damaged microcapsules. The frictional coefficient and wear rate of the self-lubricating coating decrease dsignificantly as compared to the neat epoxy. The formation of a transfer film from releasing tung oiland the entrapment of wear particles in the cavities left by the ruptured microcapsules were the majoran tifriction mechanism.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|