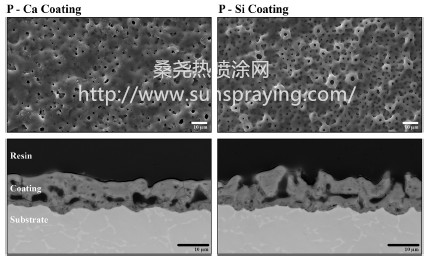

Plasma electrolytic oxidation (PEO) has been successfully used for the titanium and its alloys in order to improve its surface characteristics. PEO process allows the formation of a thicker oxide layer than formed naturally (10 nm). PEO process is carried out above the dielectric breakdown of the coatings, generating the formation of micro-discharges at high potentials. The coatings formation under the micro-discharge phenomenon results in a coating with a porous structure due to the local high temperature during the plasma events, which in turn leads to the formation of crystalline coatings. One important fact of PEO process is that the chemical composition of the coatings depends on the species contained in the electrolyte and consequently, the coating composition can be modified according to its application. Phosphate-bases electrolytes, which are widely used to form coatings for biomedical applications, induce the incorporation of phosphorous and the formation of phosphates species that assists the osseointegration processes. Some additives in the phosphate- based electrolytes influence the tribological and corrosion properties of the PEO coatings. Silicate additions improve the wear behavior and corrosion resistance of PEO coatings as was evidenced in a previous work as well as induce bone formation. EDTA and calcium acetate are commonly used as additives in the anodizing electrolyte to induce the incorporation of Ca and control the incorporation of P into the coating as well as generates coatings with low friction coefficient against stainless steel. In addition, a control of the electrical parameters during coating formation allows controlling the porosity that improves mechanical and tribological properties. Likewise, PEO coatings obtained in phosphate-based electrolytes has been shown the ability to induce the formation of apatite with the immersion in SBF on the coating surface improving the bioactivity characteristics of the coating. Coatings were obtained in electrolytes with different phosphorus source by Plasma Electrolytic Oxidation (PEO). Anatase phase (TiO2) is the main crystalline phase and rutile phase is in a minor proportion in coatings. Electrolyte with metasilicate of sodium as additive generates micro-discharges of higher size and intensity during PEO process, increasing the amount of rutile in the coating. Coatings improve wear behavior of substrate. Under the lubricated condition in Simulated Body Fluid (SBF), the formation of an amorphous layer of apatite during lubricated wear test improves the performance of coatings, allowing to slide a higher distance (100m of sliding distance) without a significant wear in the coating against the unlubricated condition (15 m).

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|