Bulk metallic glasses (BMG) exhibit interesting mechanical properties since they combine a high fracture stress, a particularly large elastic domain (up to 2%) and significant fracture toughness. An other interesting property of BMG is their ability to produce nanocomposite materials after heat treatments nearby the glass transition temperature Tg. Consequently, the effect of partial crystallization on the mechanical properties of BMG at room temperature has been also investigated. Crystallization up to a critical level (often found nearby 30–40 vol. % of crystals[3]) generally results in an increase of the fracture stress σF and then to a drop of σF.

The effect of crystallization of Vit1 on the mechanical properties at room temperature was investigated thanks to uniaxial compression and nanoindentation tests. To get well-contrasted population of crystals, appropriate heat treatments have been selected. When the degree of crystallization remains limited (typically less than 20% of ultra-fine quasi crystals), the fracture stress is slightly higher than for the amorphous alloy and the fracture surface morphology still exhibit a vein pattern. For large degrees of crystallization (for which a large variety of crystals is present with significant contacts between them), the fracture stress is sharply reduced and the fracture surface morphology is of cleavage type. From nanoindentation tests, some information about the Young’s modulus and an apparent yield stress can be obtained. Predictions, based on the assumption that all the studied samples exhibit the same strain hardening parameter support the idea that crystallization induces an important increase of the yield stress. However, AFM observations of the imprints suggest that the mechanism of deformation varies noticeably with crystallization.

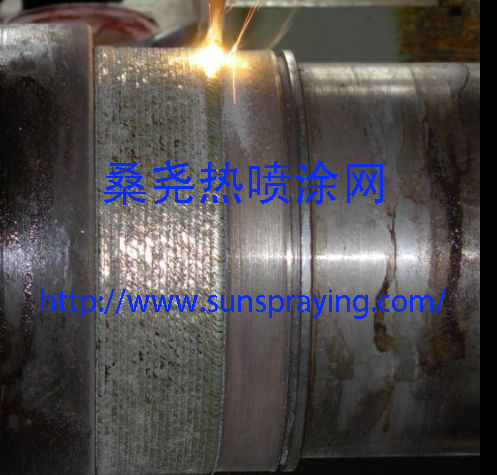

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|