The efficiency of all types of gas turbine engines, aircraft, terrestrial and marine, is proportional to firing or turbine inlet temperature. Increases in temperature are facilitated by improved structural design and airfoil cooling technology applied to higher strength-at-temperature alloys cast by increasingly complex processes, and coated with steadily improved protection systems. First stage turbine blades, the most critical components of gas tubines, made from nickel-base superalloys in various wrought and cast forms, and augmented by coatings, have been singularly successful materials systems for the past 50 years.

The use of coatings on gas turbine airfoils, in concert with improved alloys and design technology, has unfailingly supported increases in either or both efficiency and service life in varieties of turbomachinery. Early coatings were simple diffusion aluminides applied principally by pack cementation and later by gas-phase processes. Additions of silicon, chromium and platinum improved the service lives of these coatings. Parallel research in oxidation and hot corrosion mechanisms, coating processing, and mechanical properties of coating–alloy systems have provided sound bases to guide the intelligent use of the coatings over several decades. Research aimed at understanding protective oxide adherence supported the development of MCrAlY overlay coatings which offered the ability to tailor properties for practical uses in a variety of gas turbine applications. Early uses of zirconia-based thermal barrier coatings on burner components signaled possibilities of the coatings to substantially extend turbine airfoil lives and/or improve engine efficiencies.

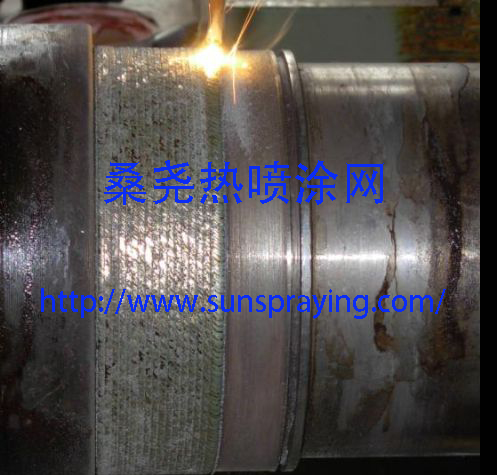

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|