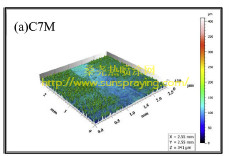

In this work, a series of Cr2O3 composite coatings have been prepared by APS with different additives, including single metals, single ceramics and metal/ceramic assembles. According to the previous research, Nb2O5 ceramic can be used as enhancement phase in Cr2O3 coatings due to its relatively low fusion temperature and high hardness. In addition, MoO3 ceramic could be considered as reinforcing phase and solid lubricant to improve the tribo-properties of Cr2O3-based coatings. The metal Mo has good wear-resistant and corrosion resistance. It has been reported that Cr2O3-8wt.% TiO2 and Cr2O3-5wt.% SiO2-3wt.% TiO2 coatings both have excellent wear resistance. The purpose of this paper is to mainly study the effects of metal/ceramic co-doping on the sliding wear characteristics of Cr2O3 coatings. Considering the soft metal phases would weaken the hardness of the composite coatings, some adjustments have been made in this work to the doping amounts of two phases. The doping amount of metal phase was determined to be 3 wt% and that of the ceramic phase was designed to be 4 wt%. Finally, Cr2O3-7wt.% Mo(C7M), Cr2O3-7wt.% Nb2O5(C7N), Cr2O3-4wt.% MoO3-3wt.% Mo(CMM), and Cr2O3-4wt.% Nb2O5-3wt.% Mo(CNM) composite coatings were prepared. Their sliding wear properties were compared under the low and high loads. In addition, the phase composition, microstructure and microhardness of these composite coatings were evaluated. The doping or co-doping effects of metals and ceramics on the coating properties were clarified. Metal/ceramics co-doped coatings (CMM, CNM) display denser microstructures and lower porosities, especially less interlamellar pores, than C7M and C7N coatings. The microhardness of Cr2O3 composite coatings is more related with the hardness of the doped material itself than with the coating porosity, after all the coatings have relatively dense microstructure. 2) Encountered against WC-Co or Si3N4 balls under low loads (5 N), the friction coefficients of the composite coatings have inverse relationship with their microhardness. The coatings mated with WCCo counterparts have lower friction coefficients than those against Si3N4, but more obvious fatigue wear characteristics. The material transfer occurs under both conditions. 3) Under sliding conditions with high loads (50 N), Mo/Nb2O5 codoped Cr2O3 coating (CNM) has the best wear resistance than other coatings. This results from the delaying co-effects of crack formation and propagation on basis of the crack deflection and the toughening effects of Mo additives and the high hardness of Nb2O5 additives.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|