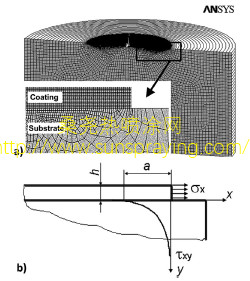

One-layer coatings are the most studied ones; their main drawback is that they quickly wear out with repeated impact loads caused by erosive particles. An obvious solution is to create a multi-layer coating that combines hardness to withstand the brittle fracture and sufficient impact strength. In addition, the alternation of layers with different properties makes it possible to design an optimal coating structure with account of internal stresses. In this regard, the main goal of this work is to study the dependence of erosive wear of multilayer PVD coatings deposited on the Ti-6Al-4V alloy according to their “architecture” (the number and thickness of layers). The finite element modeling (FEM) and physical experiment are used to evaluate the effect of internal residual stresses and mechanical stresses arising on the surface of the sample with a multilayer coating on the wear under impact load. The current study examines the erosion wear dependence on the “architecture” (the number and thickness of layers) of multilayer PVD coatings applied on the Ti-6Al-4V alloy. Finite element modeling and physical experiments were used to evaluate the effect of internal residual stresses and mechanical stresses arising on the surface of samples with multilayer coatings on the erosion wear under impact load. The adhesive strength of the coating was determined by the scratch test. It is shown that use of multilayer ion-plasma coatings on the basis of Ti-TiN, Ti+TiVN, or Ti+TiZrN with different combinations of the number and thickness of intermediate layers is an effective way to increase the erosion wear resistance. The erosion rate was decreased by 10 times in the Ti-6Al-4V samples by application of the Ti-TiVN coating.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|