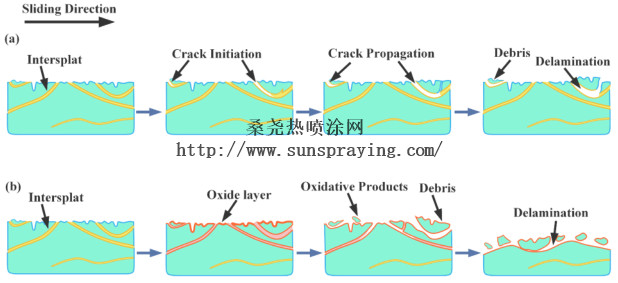

Elevated-temperature wear behavior, which is a phenomenon that exists in broad areas of industries, such as certain moving parts in internal combustion engines, bearings in aerospace propulsion systems, hot forming tools, and metalworking processes, is inevitable and complicated. In general, the elevated temperature affects tribological performance through the following three aspects: bulk properties, reactivity, and tribo-layer forming tendency. Mechanical property and oxidation resistance are remarkably dependent on environmental temperature and atmosphere, therefore, investigating the elevated-temperature tribological properties of Fe-based ACs has considerable research and practical significance. A new kind of non-ferromagnetic Fe-Cr-Mo-W-C-B-Y bulk metallic glasses with high GFA, superior thermal stability, outstanding hardness, and excellent tribocorrosion resistance is recently synthesized .In this work, Fe-based AC with a nominal composition of Fe43Cr20Mo10W4C15B6Y2 (at.%) was prepared using an activated combustion HVAF (AC–HVAF) thermal spraying system. The elevated- temperature (below the glass transition temperature, Tg) tribological performance of Fe-based ACs was systematically discussed by performing ball-on-disk rotating sliding tests under various temperatures and atmospheres. Microstructure, mechanical properties, and elevated-temperature (below the glass transition temperature) tribological performance of the activated combustion–high velocity air fuel (AC–HVAF)-sprayed Fe-Cr-Mo-W-C-B-Y amorphous coating (AC) were investigated. In vacuum, the enhanced hardness favored the wear resistance of Fe- based AC as the temperature rose from 293 K to 673 K. Moreover, the wear mechanism was modified from abrasive wear accompanied by delamination and adhesive wear to the delamination and adhesive wear. In air, the oxidation reaction worsened the splat-to-splat bonding and accelerated the wear rate of Fe-based AC at 673 K. Meanwhile, the elevated-temperature wear failure was the delamination, adhesive, and intensified oxi-dative wear. Fe-based AC exhibited superior elevated-temperature wear resistance, demonstrating its significant prospect as a wear-resistant coating material for aggressive elevated-temperature applications.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|