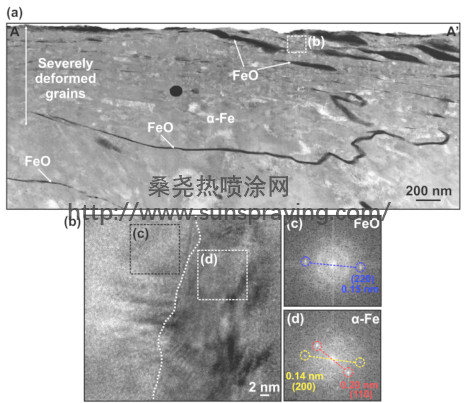

For the tribological design of the cylinder bore-piston ring interface, the top compression ring (TCR) of the piston ring package is considered to be among the most critical components as the highest stress levels are reached near the top dead center (TDC) of cylinder bore surface on the firing stroke cycle. Severe wear (scuffing) is normally observed to initiate at the reversal positions especially the TDC, as boundary lubrication prevails (and oil starvation may occur) at this location. In a highly loaded diesel engine with PTWA 1010 steel coated cylinder bore surfaces tested for 56,700 km in an engine oil (10W40), a 50–100 nm thick tribolayer rich in C, O, and Fe was observed at the TDC of the bore surface, indicating the formation of a mixture of iron oxides and combustion residues. Zinc dialkyl dithio phosphate (ZDDP) is a common anti-wear agent used in the formulated engine oil. The formation of sulphide and phosphate particles as a result of decomposition of ZDDP in the tribolayers, typically consisting of an amorphous carbon matrix, has been reported. It was suggested that the pressure-induced cross-linking of zinc phosphates could be responsible for the functionality of these 'anti- wear' tribolayers. In the tribosystems involving ferrous compo- nents, ZDDP may react with iron oxides (a mixture of Fe3O4 and FeO) during sliding process, and a reduced COF could be observed as a result of the formation of a multilayered tribofilm containing Zn, Fe, S, P and O. It has been reported that iron oxides on steel surfaces could react with ZDDP decomposition products to form iron salts such as iron phosphate and zinc/iron polyphosphates. From the above review, it becomes clear that the oxidational wear of thermal spray coated bore surfaces and its effect on friction need to be further studied. This work aims to delineate the compositions of iron oxide phases generated during oxidational wear under dry and lubricated conditions, and elucidate how sliding wear would affect COF values. The relationships between oxidational wear, surface roughness and COF were established by constructing the Stribeck curves that show the changes in COF under the boundary and the mixed lubrication regimes. Reciprocating tests were conducted with the variation of reciprocating frequency using base oil (POE) with and without ZDDP addition. Worn surfaces were characterized by electron microscopy and spectroscopic methods to determine the morphologies and compositions of the tribolayers generated during sliding. The development of thermal spray steel coatings for Al-Si engine blocks with wear resistant cylinder bores constitutes an important aspect of automotive light weighting strategy. In this work tribological behaviour of low carbon steel cylinder bore coatings produced by a plasma transferred wire arc (PTWA) method were studied using samples sliding against CrN coated top compression ring samples. The focus of the work was to study the role of oxidational wear on the friction behaviour of spray coatings consisting of α-Fe splats delineated by thin FeO layers. In-situ Raman spectroscopy was employed to observe the oxide transformations that occurred during dry and lubricated sliding tests conducted using a reciprocating tribometer. Lubricated sliding tests were performed within a speed range of 0.02–0.92 m/s covering the boundary and mixed lubrication conditions using a Polyol ester, POE, base oil with and without zinc dialkyl dithio phosphate (ZDDP) addition. The use of ZDDP containing POE led to the generation of an amorphous carbon tribolayer incorporating ZnS and FePO4 nanocrystals that inhibited sliding-induced Fe2O3 debris formation, and consequently resulted in a reduced wear rate, but the steady-state coefficient of friction (COF) was higher during the boundary lubricated sliding. According to the Stribeck curves generated, the prevention of oxidational wear by the formation of oil residue layer delayed the transition from the boundary lubrication to the mixed lubrication regime.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|