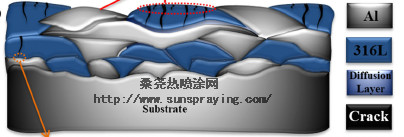

In order to better solve the Al alloy wear problem, arc spraying has been recognized as the most effective and practical onsite repair solution. Arc spraying is acknowledged as a simple and cost-effective thermal spray technology. In addition, 316L austenitic stainless steel coating is widely used in engineering and mechanical fields. It has the advantages of low cost and high chemical stability and wear resistance. Previous research has shown that during the deposition of atomized stainless steel particles, serious oxidation and deformation occurs, which leads to the formation of microcracks and the formation of residual stress. In order to reduce oxidation and residual stress of thermal spraying stainless steel coating, Al/stainless steel composite coatings with different wear properties were prepared by arc spraying technology. The ductile/hard phase's layers are mechanically bonded, the residual stress is also large, and the microstructure, element distribution and wear mechanism between the layers are not well explained. Thus, the composite coating wear mechanism was thoroughly revealed, and achieving a solution that achieves low cost, long wear lives of Al alloy surfaces is still an important goal. Al/316L stainless-steel composite coating was successfully prepared by two-channel-synchronization wire feeding arc spraying technology. The composite coatings wear performance and mechanism were analysed by their tribological behaviour. a) Al/316L stainless-steel composite coating has a ductile (Al splat)-hard (stainless-steel splat) interpenetration structure, in which the wear failure mechanism is the shallow flaking of fatigue wear.b) Wear resistance of the composite coating higher than that of the stainless-steel coating is three times. The composite coating improves the Al alloys wear resistance by a factor greater than nine.c) In composite coating, the ductile (Al splat) -hard (stainless-steel splat) structure promotes the formation of Fe3O4 and interpenetrating structures, improving the wear resistance and crack propagation resistance of the composite coating.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|