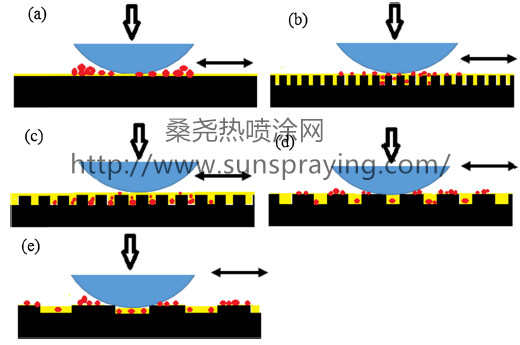

Surface texturing is a relatively novel technique to improve the tribological performance of mechanical components. In this technique, micro-textures and nano-textures are created on mechanical component surfaces to reduce wear, friction and temperature at contact. To obtain these benefits, researchers are optimizing geo-metric parameters of texturing, including density, diameter, depth, and placement angle of dimples, for particular operating conditions. Several mechanisms, such as providing additional fluid pressure in hydrodynamic lubrication , acting as micro traps for wear debris to minimize third body abrasion, and in creasing load carrying capacity by providing lubricant under high loads, have been proposed to improve tribological performance. Micro dimples were created on a substrate by using a picosecond laser. After surface texturing was performed, amorphous hydrogenated diamond-like carbon (DLC) coating was deposited through magnetron sputtering. Dimpledia meter varied from 50 m to 300 m, and dimple depth varied from 6 m to 30 m. Results show that at respective dimple diameter and depth of 100 m and 6 m, surface texturing improved the tribological performance of the amorphous hydrogenated DLC coating. Whereas, at a higher dimple diameter of 300 m and dimple depth of 30 m, the tribological performance of textured amorphous hydrogenated DLC was worse than that of un-textured amorphous hydrogenated DLC. The performance enhance mention the case of dimple diameter and depth of 100 m and 6 m can be due to micro textures, which can serve as a lubricant reservoir at the interface during sliding and remove wear particles from the contact. However, this beneficial mechanism could be obtained at an optimum texture diameter and depth.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|