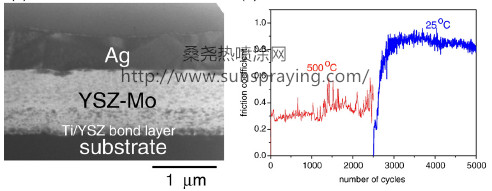

Solid lubrication over a wide range of ambient atmospheres is a challenge that tribologists have faced for decades and have yet to overcome, as most lubricants perform usefully (e.g., a friction coefficient b0.2) only within a narrow window of ambient conditions. Temperature ranges of solid lubricants are particularly difficult to broaden. The most well-known solid lubricants, such as graphite, molybdenum disulfide, and PTFE are effective from low temperatures up to 250–400 °C in air, above which the materials oxidize or decompose and lose their lubricious nature. Some oxides lubricate well above 600–800 °C, but are abrasive at lower temperatures. One successful approach towards blending multiple lubricants and using their interaction with the environment to generate self-lubricating contact surfaces for a range of ambient conditions can be found in nanocomposite tribological coatings that employ a “chameleon” adaptive coating concept. In these coatings, nanoscopic volumes of lubricious phases are contained within a tough, hard, chemically inert and thermally stable matrix. Such materials demonstrate multiple thermally-activated mechanisms for alteration of surface composition and morphology to provide a low shear interface between the ceramic matrix and the wear counterpart. Nanocomposite materials demonstrating multiple temperature-adaptive mechanisms including diffusion, oxidation and/or catalysis mechanisms to yield low friction coefficients of b0.2 from room temperature to 700 °C were combined with diffusion barrier layers in coatings with different architectures (e.g., layer thicknesses, number of layers, etc.) to examine adaptation of contact surface chemistry and morphology over multiple thermal cycles. Multilayered coatings consisting of ceramic–metal nanocomposite adaptive lubricant layers separated by diffusion barriers allowed adaptation to occur only upon exposure of the lubricant layer by wear, which resulted in prolonged wear life at static and cycled temperatures. It was also observed that a relationship between the number of adaptive lubricant layers and the number of thermal cycles existed, where one thermal cycle consumed two adaptive lubricant layers. The thickness of the adaptive coating layers was also important because diffusion- and oxidation-based adaptation in these particular coatings required a minimum volume of solid lubricant material. The surface roughness of the adaptive coating materials played a significant role in their performance within multilayered coatings, where rough coatings (N100 nm Ra) failed after relatively few sliding cycles. The utility and application of adaptive coatings materials providing lubrication over multiple thermal cycles is discussed.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|