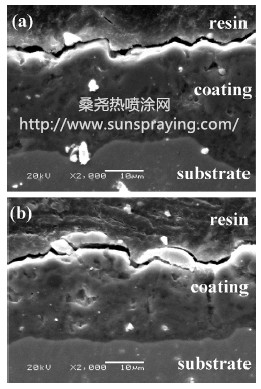

The tribological properties of the PEO coatings prepared on the surface of titanium alloys have been studied by many scholars under dry and lubricated sliding conditions in recent years. Wang et al. investigated the tribological properties of oxide coatings synthesized by MAO on the surface of Ti6Al4V alloys. Vangolu et al. studied the effects of micro-arc oxidation and hydrothermal treatments on morphology and in vitro wear properties of Ti6Al4V alloy. The results of these studies showed that the PEO coatings provided good wear resistance to the titanium alloys but normally exhibited higher friction coefficients under unlubricated conditions. In many tribological applications, high friction coefficient could lead not only to the wear of the slider, but also to the wear damage of the counter material. In order to improve further the tribological properties of the PEO-treated titanium alloys, some attempts of duplex approaches to reduce the friction coefficient of the PEO coatings have also been made. For example, duplex processes, in which low-friction topcoats (e.g., graphite and PTFE) were deposited onto the PEO coatings, have been considered by some authors. As an alternative and effective approach, in present investigation, a one-step PEO process in a graphite-dispersed electrolyte was used to produce graphite-containing oxide coating on Ti6Al4V alloy for a low friction coefficient tribological behavior. The composition, structure and tribological properties of the graphite-containing oxide composite coating were studied. One-step plasma electrolytic oxidation (PEO) process in a graphite-dispersed phosphate electrolyte was used to prepare a graphite-containing oxide composite coating on Ti6Al4V alloy. The composition and microstructure of the oxide coatings produced in the phosphate electrolytes with and without addition of graphite were analyzed by X-ray diffractometer (XRD), Raman spectroscopy, X-ray photoelectron spectroscopy (XPS) and scanning electron microscopy (SEM). The tribological properties of the uncoated Ti6Al4V alloy and oxide coatings were evaluated using a reciprocating ball-on-disk tribometer. Results showed that the graphite-containing oxide composite coating can be successfully produced on Ti6Al4V alloy in the graphite-dispersed phosphate electrolyte using PEO process. The graphite-containing oxide composite coating registered much lower friction coefficient and wear rate than the uncoated Ti6Al4V alloy and the oxide coating without graphite under dry sliding condition, exhibiting excellent self-lubricating property.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|