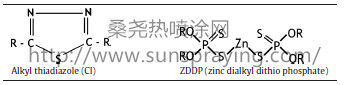

EP additives are usually added to the lubricating oils to provide resistance to the surface from extreme pressure/temperature conditions. The commonly used EP additives such as Sulphur and phosphorous based additives improve the scuffing load and provide wear resistance against extreme pressures by forming surface films. Sulphur-based EP additives (sulphurised fatty oils and sulphurised oliefin) react with the ferrous surface to form iron sulphide to reduce wear and prevent seizure. The very low hardness and shear strength of iron sulphide, combined with good adhesion to iron and steel surfaces, are key properties of S-based EP tribofilms to ensure friction reduction and hinder scuffing. Similarly, the phosphorous-based EP additives (alkyl amine phosphates and alkyl phosphate ester acid) react with surfaces to form phosphate compounds to provide the required surface protection. In general the reactivity of the P-based EP additives has a good correlation with wear-resistance and EP performance. Phosphates and phosphites have comparable performance in terms of wear and EP protection to align with their similar chemical reactivity on the steel surface. In addition to additives specifically used to give EP performance it is important to understand how additives used for antiwear/antioxidancy (e.g. ZDDP) and corrosion inhibition (e.g. thiadiazole) behave in EP conditions. Both of these additives in other studies have been shown to impart some EP performance but in this study their inclusion is primarily as antiwear and corrosion inhibitors, respectively. Improvement of fuel economy and component durability as well as reduction of dependence on some harmful components of lubricants are the key concerns for automotive industries. In recent years, efforts have been made to use surface engineered surfaces in automotive components to produce environmentally friendly vehicles as well as to increase fuel economy. Since commercially available lubricants are mainly optimised for effective lubrication of ferrous materials, effective lubrication of novel materials, especially in the boundary lubrication/EP regime, is not well understood. Published research has also indicated that lubricant chemistry could have a detrimental impact on the intrinsic coating properties, changing their mechanical properties. Tribological systems working in boundary lubrication/EP conditions rely on lubricant–additive interactions to initiate surface reactions. The performance (frictionrelated efficiency and wear-dependent reliability) of tribological systems depends on the time taken to initiate surface reactions, the nature of the surface reactions and the stability of the films formed as a result of the surface reactions. This paper is a fundamental study of the lubrication and wear mechanisms of a WC-doped diamond-like-carbon (DLC) coating when lubricated in the extreme pressure (EP) regime.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|