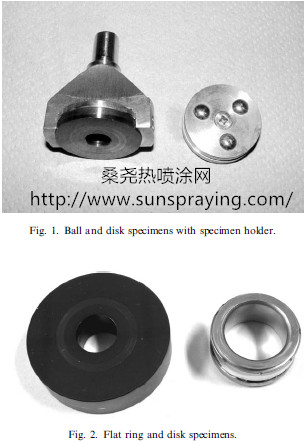

Tribology makes a substantial contribution to reducing CO2 evolution and protecting the natural environment. Such efforts in tribology are being performed in many engineering fields. For example, in the automotive industries, with the cooperation of the lubricant manufacturers, an improvement of fuel economy is achieved by reducing the engine oil viscosity to reduce viscous resistance, and by using a friction modifier to reduce the boundary friction at solid contacts. The effort to increase the boundary friction characteristics of belt-type continuously variable transmission fluids (b-CVTF) also contributes to the fuel economy because it can increase the slip limit. In addition to these changes in the automobile industry, many technical improvements are also being made to protect the global environment. Use of water as a working fluid in the hydraulic system instead of conventional mineral oil has many advantages for reducing the amount of CO2 evolution and protecting the natural environment. The low viscosity of water can reduce the energy consumption of the pumping system, the use of water does not require transportation of a large amount of hydraulic fluid from lubricant manufacturers to the factory and thus helps to reduce fuel consumption, and the use of water can reduce the amount of used hydraulic oil to be disposed. In addition, in the food industry, it is important to avoid contamination of foodstuffs with lubricating oil. From the viewpoint of environmental protection, it is desirable to use water without additives, such as corrosion inhibitors, lubricating additives, and so on. Since neither conventional carbon steel nor stainless steel can be used as a tribomaterial in water hydraulic systems due to corrosion or lack of lubricity, use of engineering ceramics or plastics is one of the solutions for establishing such a system. It is well known that silicon nitride (Si3N4) and silicon carbide (SiC) show good lubricity in water environments. However, these Si-containing bulk ceramics are scarcely applicable for machine components, because of their many disadvantageous properties, including cost, brittleness, difficulty in machining, and so on [8]. To establish reliable water hydraulic systems, it will be necessary to develop new materials for tribosurfaces, and the development of reliable coatings will be a key technology in this effort. Water has been considered as an alternative working fluid for hydraulic power systems in order to minimize the consumption of fossil fuels and mineral oils. In spite of the many advantages to this use of water, difficult technical problems remain. The key technology for establishing a water hydraulic system is tribology, because water has a lack of lubricity, and thus some coating is needed to protect the metal surfaces from corrosion and frictional wear when using water as a lubricant. It has already been demonstrated that some Sicontaining materials have good lubricity in a water environment. Recently, it has been shown that diamond-like carbon (DLC) coatings also have good lubricity with water. In order to clarify the mechanism by which such materials are lubricated with water, and to develop surface coatings that have good lubricity with water, the friction characteristic of several coated metals were investigated in this study. Coatings of CrN, CrSiN, and two types of DLC were applied on an SUS630 stainless steel flat disk substrate. Additive-free distilled water was used as a lubricating fluid. The friction characteristics of these coatings at different sliding speeds were evaluated using a tribometer with two contact configurations in which stainless steel balls and a flat ring without coatings were used as mating specimens.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|