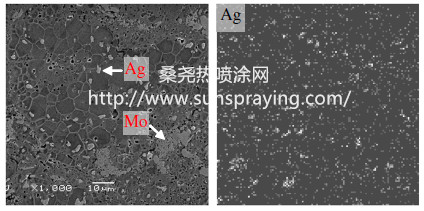

Solid lubricant coatings are primarily employed in extreme environment applications, especially in high temperature environments (above 500 °C), where conventional materials and lubricants cannot be used. Typical solid lubricants, such as graphite and MoS2, cannot be used at these cases because of their inadequate oxidation resistance. So it is necessary to develop self-lubricating materials with excellent friction reduce property at high temperatures. The main problem of using solidslubricants is that these materials possess low shear strength at high temperature. Many compounds, such as soft metals, oxides, molybdates and tungstates, are promising as solid lubricants at high temperatures. Some molybdates and tungstates showlow friction, for example, K2MoO4 (0.20), Ag2MoO4 (0.28), NiMoO4 (0.29) and Na2WO4 (0.17) at 704 °C. However, these materials are undesirable at low temperatures. Sliney et al. prepared a new series of high temperature selflubricating solid materials over a wide temperature range. These composites are comprised of awear-resistantmatrix (Ni–Co–Cr3C2, Ni–Cr–Cr2O3) combined with silver and BaF2/CaF2 eutectic solid lubricants, which provide good friction and wear properties from room temperature to 850 °C. After that, some self-lubricating solid materials were designed to service at high temperatures. Murakami et al. replaced the Ni–Cr alloy phases in the composites with Al2O3 and NiAl phases, and used BaF2–CaF2–SrF2 as eutectic solid lubricants. The composites showed the low friction coefficient (0.3–0.4) at temperatures between room temperature and 800 °C. A self-lubricating ceramic matrix (Al2O3) composite with Ag/CaF2 fabricated by powder metallurgy method provided low friction and wear over a temperature range of 300–650 °C. In recent years, a series of Ni3Al matrix composites containing Ag/BaF2–CaF2 as solid lubricants were prepared by powder metallurgy technique, and showed good self-lubricating property at a wide temperature range in air (from 25 to 1000 °C). The composites exhibited low friction coefficients (0.3–0.4) and low wear rates. A Ni3 Al–Ag–Mo–BaF2/CaF2 self-lubricating composite coating was fabricated by a powder metallurgical process. The tribological properties of the coating against Si3N4 were investigated over a wide temperature range (25–1000 °C). The results showed that the coating had a low friction coefficient (0.24–0.38) in the entire temperature range. Lubricating mechanism analysis results indicated that Ag took effect at low temperature (below 400 °C); BaF2/CaF2 began to work as a solid lubricant as the temperature raised; and the molybdates, which formed by the fluorides oxidation, act as lubricants at higher temperatures (above 800 °C). As a result, the coating expressed a low friction coefficient from 25 °C to 1000 °C.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|