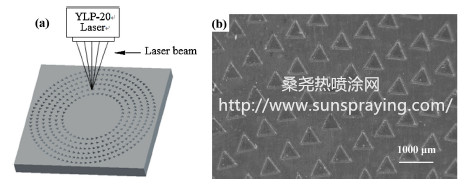

Surface coating is another effective way to improve the tribo-logical performance of components, such as metal forming tools. Here, TiN coatings have been widely used in industry as wear resis-tant coating, especially for forming tools due to their high hardness, favorable corrosion resistance and good chemical stability.Previous researches studied the tribological behavior of TiN coat-ings and suggested that the tribological performance was closelyrelated to the microstructure, residual stress and mechanical prop-erty of TiN coatings. Moreover, the coatings process has aneffect on the tribological performance of the TiN coatings, and theresults suggested that the hardness, plastic deformation resistanceand wear behavior of TiN coatings had increased remarkably afterion implantation, and the element content of coatings also hasa certain influence, and the frictional coefficient of TiN coatingsdecreased with the increase of chlorine contents.To further enhance the tribological performance of TiN coatings,quite a few researches applied surface texturing on the coatings,and the results indicated that textured TiN coatings have an excel-lent tribological performance in different applications. ThePVD-TiN coatings of tool steel had discontinuous surface archi-tecture, which significantly decreased the friction, wear and thewearing speed of tool steels and improved its lifetime [19]. Tex-tured TiN coatings also have been applied to die steels, but thestudies are extremely limited, the results stated that in-lined andstaggered spot-island patterned coatings possessed relatively bet-ter wear behaviors than the fully coated discs. Most of the researchers investigated the tribological perfor-mance of cycle-textured TiN coatings on the surfaces of cuttingtools or alloy steel. However, limited studies have analyzed thetribological behaviors of triangular-textured TiN coatings on thesurface of stamping die steel. Considering the stamping process isunidirectional and the convergence speed of triangular texturingfrom a vertex angle to the side is fast under oil lubrication,the present work aims to studying the effect of triangular surfacetexture on the tribological performance of the die steel substratewith TiN coatings by carrying out the oil lubrication sliding tests ona pin-on-disk tribometer. tThe friction and wear of stamping die surface can affect the service life of stamping die and the qualityof stamping products. Surface texturing and surface coating have been widely used to improve the tri-bological performance of mechanical components. This study experimentally investigated the effect oftriangular surface texture on the friction and wear properties of the die steel substrate with TiN coatingsunder oil lubrication. TiN coatings were deposited on a die steel (50Cr) substrate through a multi-arc iondeposition system, and then triangular surface texturing was fabricated by a laser surface texturing. Thefriction and wear test was conducted by a UMT-3 pin-on-disk tribometer under different sliding speedsand different applied loads, respectively. The adhesion test was performed to evaluate the effectivenessof triangular texturing on the interfacial bonding strength between the TiN coating and the die steelsubstrate. Results show that the combination method of surface texturing process and surface coatingprocess has excellent tribological properties (the lowest frictional coefficient and wear volume), com-pared with the single texturing process or the single coating process. The tribological performance isimproved resulting from the high hardness and low elastic modulus of TiN coatings, and the generationof hydrodynamic pressure, function of micro-trap for wear debris and micro-reservoirs for lubricatingoil of the triangular surface texture. In addition, the coating bonding strength of the texturing sampleis 3.63 MPa, higher than that of the single coating sample (3.48 MPa), but the mechanisms remain to befurther researched.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|