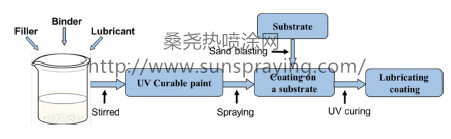

As a type of lubricating material, the bonded solid lubricating coating has been widely used in various fields where oil lubricants and grease lubricants are ineffective and undesirable to reduce the energy consumption and security risks caused by serious friction and wear between the moving parts under severe conditions, due to their excellent friction-reducing and anti-wear performances. Generally,a type of bonded solid lubricating coating is composed of binder, solid lubricant and filler. As the film-forming material, the binder determinates the curing method of entire coating. It is clear that most of bonded solid lubricating coatings reported in literature and applied in practice are cured by heating or at room temperature. However, the thermal curing process of lubricating coatings consumes too much energy and limits its applications in many heat sensitive substrates, and room temperature curing process takes too long time and leads to its low efficiency. So far, the ultraviolet radiation curing (UV curing) technique has been considered to be the most effective approach transforming the liquid paint into a solid coating at ambient temperature. Compared to the two curing approaches mentioned above, UV curing has been developed into a well-accepted technology in various fields due to its many advantages such as fast curing, less energy and resource consumption, solvent-free formulation, excellent finishing, easy operation and the like. To the best of our knowledge, unfortunately, the introduction of UV curing technology to prepare bonded solid lubricating coating has rarely been reported. In this paper, polyurethane acrylate as oligomer resin and polytetrafluoroethylene (PTFE) as solid lubricant were selected to prepare UV curing bonded solid lubricating coating, respectively. As a UVcurable material, polyurethane acrylate combines the advantages of polyurethane and acrylate, and has excellent performance like flexibility, solvent resistance, wear resistance and easy to adjust the resin performance through molecular design. As a good lubricant, PTFE possesses extremely low friction coefficient, but its abrasion resistance is very poor. To overcome this drawback, lots of previous works reported that rare earth compounds like LaF3, CeF3, La2O3, CeO2, etc, as the enhanced fillers can significantly improve the tribological properties of PTFE based bonded solid lubricating coatings. To study the influence of filler size on the tribological properties of the bonded solid lubricating coating, nano-LaF3 and micro-LaF3 were selected as fillers in this work. The polyurethane acrylate resin-polytetrafluoroethylene (denoted as PUA/PTFE) bonded solid lubricating coatings with good tribological properties were prepared by ultraviolet radiation curing (UV curing), and then nano-LaF3 and micro-LaF3 were incorporated to further improve the tribological properties of the lubricating coatings. The photopolymerization reaction of the lubricating coating binder was characterized by an attenuated total reflection Fourier transform infrared spectrometer (ATR-FTIR). A micro-hardness tester was used to evaluate micro-hardness and a CSM friction and wear tester was selected to investigate the tribological properties of the lubricating coatings under dry friction condition. The coating surfaces and worn surfaces topography, as well as the distribution of La elements, were observed with a scanning electron microscope equipped with an energy dispersive X-ray spectrometer. Results show that the final conversion of acrylic double bond reached 98.4%, and the lubricating coating showed the best adhesive strength, micro-hardness and tribological properties when the mass ratio of PTFE to the binder was 1. Moreover, the incorporation of nano-LaF3 or micro-LaF3 both effectively enhanced the micro-hardness and the wear resistance of the PUA/PTFE lubricating coatings. Furthermore, nano-LaF3 was superior to micro-LaF3 for the improvement of anti-wear performance. The main wear mechanism of the UV curing PUA/PTFE lubricating coatings was dominated by fatigue wear.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|