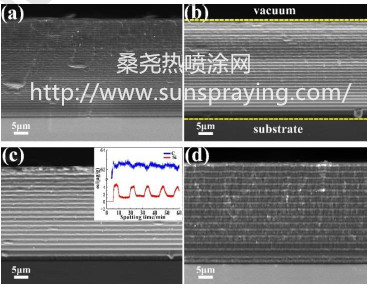

Lubricating oils, additives and oil hydraulic systems can pollute natural environments and waste resources due to oil leakage and high cost. The preparation of solid self-lubricating film or coating on the surface of machinery and parts is an effective method to reduce friction and wear. In the past few decades, amorphous diamond-like carbon (amorphous diamond-like carbon, a-C, DLC) coatings have attracted much interest due to their excellent mechanical properties, chemical inertness and outstanding tribological properties. Numerous researches have confirmed that DLC has the advantages of low friction and wear in various environments. One of the main limitations of DLC as a protective coating is that high stress and a mismatch in the chemical bonding between the coatings and substrates often cause for poor adhesion, limiting the film thickness. This results in the limitation of DLC coating in practical applications. Many approaches have been employed to minimize the residual stress and improve the adhesion of DLC films, for instance, incorporating doped elements and multilayered coatings. The advantage of the multilayer coating is not only the resistance to wear. Moreover, the multilayer structure can prevent penetration of the coating by corrosive media. Therefore, the multilayer coating can be applied to a substrate which may be exposed to frictional wear in corrosive environments. In recent years, water has been identified as a potential replacement for traditional lubricants. Therefore, with the increasing importance of ecological awareness and environmental protection in production applications, water lubrication has caused widespread concern and interest. T. Ohana et al. deposited the Si-DLC/DLC multilayer films by pulsed-bias CVD technique and reported that, the thickness of the Si-doped layer is one of the important factors for good tribological properties. E. Strmčnik et al. investigated the coefficient of friction, the wear loss and the wear coefficient of stainless steel / DLC lubricated with water. The coefficient of friction for stainless steel / DLC in water was lower than the coefficient of friction for stainless steel / DLC in oil and lower than stainless steel / stainless steel in oil. The wear loss of a DLC disc that was tested in water against steel (stainless steel / DLC) was very low. Although much work has been done on the tribological properties of DLC coatings, some problems remain to be explored and solved. For one thing, further studies on the influence of multilayered DLC coating structure design on the tribological properties in air and water lubrication conditions is of great significance for extension of DLC coatings application. For another, exploring the lubrication mechanism of DLC multilayer coating under dry and wet conditions is an effective way to understand the tribological properties.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|