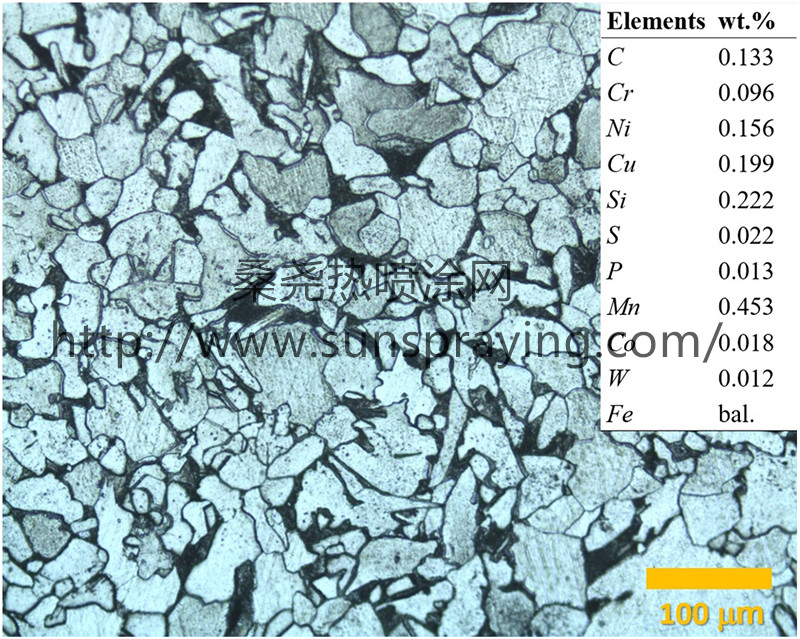

Most failures of engineering components originate from degradation processes such as fatigue, corrosion, and wear initiated at the materials' surface. Surface engineering is, therefore, essential to the development of new materials with optimized properties for application to harsh environments such as those found in the agriculture, mining, and oil and petrochemical industries. Among the commercially available alloys, steels are very attractive to be considered in such applications due to their versatile microstructure, properties, and low cost. However, conventional bare steels do not meet the safety requirements in some aggressive environments where distinguished superficial wear resistance is necessary. Surface engineering allows the use of a special material layer on low-cost substrate materials (such as steel), which is an attractive and cost-effective alternative to improve the wear resistance. In this way, the components made with inexpensive steels that display satisfactory mechanical properties can be combined with a protective layer. This characteristic of the coating technology has attracted the attention of researches over the last decades, and several layer and coating deposition methods have been reported in the literature. In particular, when a thick and wear-resistant layer is required, welding processes seem to be the most suitable. Also, a laser or electron beam can be used as a source of heat, which leads to a higher precision of melting. For instance, electron beam cladding shows interesting results due to its high efficiency, strong metallurgical bond between coated layer and substrate, possibility to fabricate thick coating layers, low dilution, low porosity, and the potential to process bulk workpieces Optical micrograph of the mild steel used as substrate (etching: Nital 5%). The bright phase is ascribed to the α-ferrite and the dark region related to the pearlite. Inset: the average of the chemical composition determined by spark optical emission spectroscopy taken in four different areas (standard deviation below 0.004).

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|