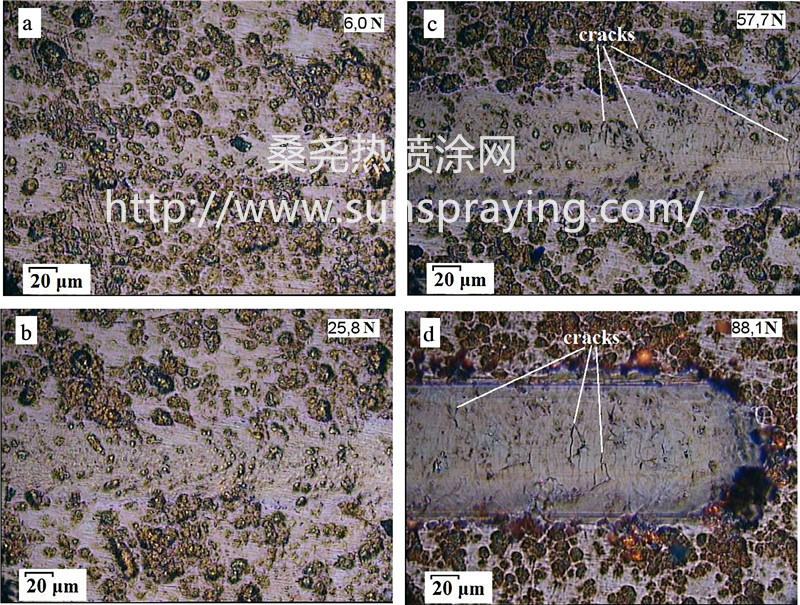

Due to its high hardness titanium nitride is one of the mostwidely used materials for production of wear-resistant coatings ofdifferent application .A lot of studies have been conducted to research modificationof structure and composition of TiN-based wear-resistant coatingsin order to improve their functional characteristics. In particular,wear resistance of these coatings can be increased by improvingtheir hardness and tribological properties following the forma-tion of products that act as solid lubricants during friction .Thus, presence of Mo in the (Ti-N) coating can cause formationof lubricious MoO3oxide during friction. It has lamellar struc-ture characterized by a low shear force of atomic planes and actsas a solid lubricant with a corresponding reduction in the fric-tion coefficient from 0.7 to 0.4–0.5. Simultaneously, an increase in microhardness values from 22 to 24 GPa to approximately34 GPa is observed in the Ti-Mo-N coatings . Introductionof additional Al should result in increased coating hardness dueto formation of microstrains in the TiN crystal lattice with sub-stitution of Ti atoms even at small Al contents (from 0.8 at.%).One of the possible methods to further improve the functionalcharacteristics of coatings in this system is to obtain complexarchitecture of coatings characterized by the presence of a nano-structure and multilayering. These structural characteristics resultin significantly improved hardness while plasticity and resis-tance to cracks formation of the coating material is maintained. tCoating samples in the Ti-Al-Mo-N system were obtained by arc-PVD method at variable bias voltage Ubapplied to the substrate, and the partial pressure of nitrogen P(N2) used as a reaction gas. The depositedcoatings were characterized by a nanocrystalline structure with an average grain size of 30–40 nm andmultilayered architecture with alternating layers of (Ti,Al)N nitride and Mo-containing phases with athickness comparable to the grain size. Coatings of (Ti,Al)N-Mo-Mo2N and (Ti,Al)N-Mo2N compositionswere obtained by changing deposition parameters. The obtained coatings had hardness of 40 GPa and therelative plastic deformation under microindentation up to 60%. (Ti,Al)N-Mo2N coatings demonstratedbetter physicomechanical characteristics, showing high resistance to crack formation and destructionthrough the plastic deformation mechanism without brittle fracturing, unlike (Ti,Al)N-Mo-Mo2N. Thefriction coefficient of the study coatings (against Al2O3balls under dry condition using a pin-on-discmethod) reached the values of 0.35 and 0.5 at 20◦C and 500◦C respectively, without noticeable wearwithin this temperature range. These tribological properties were achieved by forming MoO3acting as asolid lubricant. At higher temperatures the deterioration in the tribological properties is due to the highrate of MoO3sublimation from friction surfaces.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|