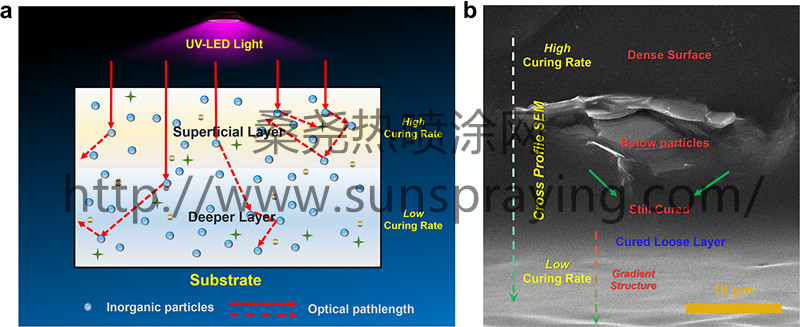

In recent years, ultraviolet (UV) curing technique has been widely used in the fabrication of polymer coatings/printing inks/hydrogels due to its unique characteristics of high curing efficiency and controllable operation. However, traditional UV curing techniques primarily relied on high-pressure mercury (Hg) lamps as the light source. This mercury lamp was prone to release large amounts of energy, which could adversely affect the performance of the final coating products,and even cause varying degrees of potential damage to operators. The challenge of making use of the advantages of UV curing techniques while avoiding the damage caused by high-pressure mercury lamp was an objective subject with assured research significance. Further researches indicated that we can transform traditional UV curing techniques into a low energy consumption and high-curing efficiency ultraviolet light emitting diode (UV-LED) technique combined with LED development. Compared to traditional UV curing techniques, the new UV-LED curing system has a longer service life and a more stable light intensity, which is consistent with the concept of environmental protection. However, the wavelength of UV-LED light source is single (almost located at 365 nm), having strict requirements on the absorption wavelength of the corresponding photo-initiator, thus may also affect the curing effect for composite system .At present, the researches on UV-LED curing materials were limited to light oil or ink, filled with low content inorganic minerals. There were few relevant studies that relied on the curing effect, influencing factors and material properties of UV-LED curing materials with high content inorganic minerals . With special consideration toward the research interest of interior wall matrix coatings, the idea, therefore, was to design and synthesize a new, densely packed (high pencil hardness), fast-cured composite material based on converted UV-LED techniques. The research also delved into the systematic investigation of various factors on the polymerization mechanism and the mechanical performance of coating materials. As shown in Scheme 1a, the coating was stirred consistently after adding inorganic mineral fillers, monomers, polymerizable diluents, and photo-initiators, then exposed to UV light for ~6 s. It was important to note that the surface of coatings always presented the cure-inhibition effect of atmospheric oxygen .Such composite systems tended to disperse into two layers with different degrees of polymerization, including a superficial layer and a deeper layer, respectively. Due to the addition of a large number of opaque mineral particles (μm-level), the ordinary UV polymerization mechanism was greatly weakened and cannot be effectively used to explain this system. A unique polymerization mechanism was supplemented and verified by varying the type and particle size of inorganic particles. From a typical cross-profile SEM image (Scheme 1b), the two regions with distinct contrast represented a superficial dense layer (dark) and a deep loose layer (light). It was observed that relatively ideal curing effect could be formed for even the positions which were located under the particles. This helped demonstrate how inorganic particles (μm-level) can become reflective or refractive points, thus reducing the barrier effect of filling particles and leading to a more densely packed (high pencil hardness) lattice. Furthermore, the general principles suitable for effect factors, in particular, reflective or refractive effects of reactants about UV-LED polymerization system were obtained . AgNPs (nm-level) were then added to this composite material to fabricate a long-term antibacterial interior wall base coating, which remained stable over a 15-week period against bacteria with the bactericidal coefficient of approximately 99.5% for E. coli and about 97% for S. aureus. This new and easily applicable polymerization method will greatly enrich the current UV polymerization system. The newly designed wear-resistant, densely packed (high pencil hardness), and long-term antibacterial coating will also have great application prospects in wall decoration field.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|