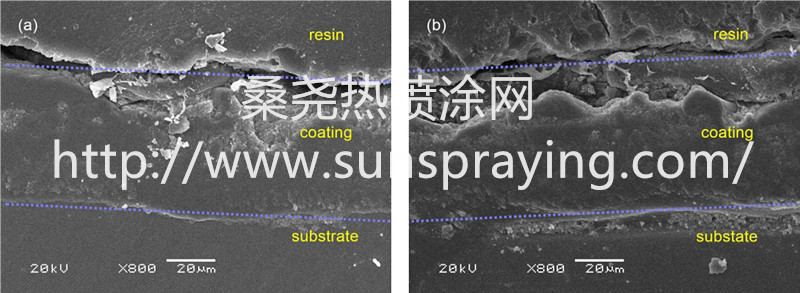

The development trends and application requirements of lightweight for the defense industry, transportation and textile industry become increasingly evident . With respect to the iron and steel materials, aluminum and its alloys have low density, high strength, easy molding and many other advantages, which can lighten weight, reduce the moment of inertia and raise speed. In terms of applicability, aluminum and its alloys have become the second place to the steel metal materials. However, the poor cor-rosion resistance, abrasion resistance and scratch resistance lim-ited the directly application. Therefore, suitable surface mod-ification should be done. For aluminum and its alloys, the research, development and application about surface treatment technology will provide a good surface protection feature and further expand their field of application. These treated materials have been known as one of the pillars of the 21st century . The plasma electrolytic oxidation (PEO) is considered as an economical and effective surface modification technique of anodic oxidation and primarily applied to aluminum and other light alloys such as magnesium, titanium and zirconium . It promotes the transformation of these metals substrate into hard and compact ceramic coatings of Al2O3, MgO, TiO2, and ZrO2 oxides by the interaction of anodic oxide growth and microelectric channel shock caused by dielectric breakdown at high voltages, taking place in an aqueous electrolyte . Complex compounds are syn-thesized between the substrate and the electrolyte through the plasma chemical interactions, and hard oxide ceramic coatings were fabricated on the metal surface simultaneously . Especially, PEO technology can form a continuous hard porous alumina ceramic layer on the surface of aluminum or its alloy, which can effectively improve the friction conditions. High hard-ness, high impedance and high stability of PEO coatings may be beneficial to meet seawater, high temperature corrosion environ-ment, and also can improve wear resistance to adapt other per-formance requirements. However, the ceramic coatings tend to have higher friction coefficient. It is easy to result in the wear failure itself, but also will exacerbate the dual material wear. Therefore, in order to further improve the friction and wear per-formance of PEO coatings, the friction coefficient must be reduced. An effective method is to prepare self-lubricating coating con-taining solid lubrication. However, the self-lubricating PEO coat-ings containing lubricating materials were usually fabricated by two-step methods . The productions of self-lubricating alumina–graphite composite coatings were prepared through one-step plasma electrolytic oxidation in an appropriate graphite-dispersed electrolyte solution, and the microstructure, composition and phase constituents were examined. The friction and wear properties were investigated by sliding the disk samples against Si3N4 balls under dry and deionized water con-ditions, respectively. Molecular dynamics simulations about the interface states of graphite were also carried out to assist in the evaluation of the self-lubricating and wear-resistant mechanisms, making up the weakness of the conventional experimental method in microscopic study. The results indicated that the oxidation coatings greatly improved the wear resistance of pure aluminum. Further improvement in the wear resistance was achieved by self-lubricating of solid lubricant in oxidation coatings. In wear process, the wear debris aggregated together on the worn surface and the graphite particles formed layered structures, which exhibited excellent self-lubricating behavior and decreased the shear stresses generated by the moving stylus.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|