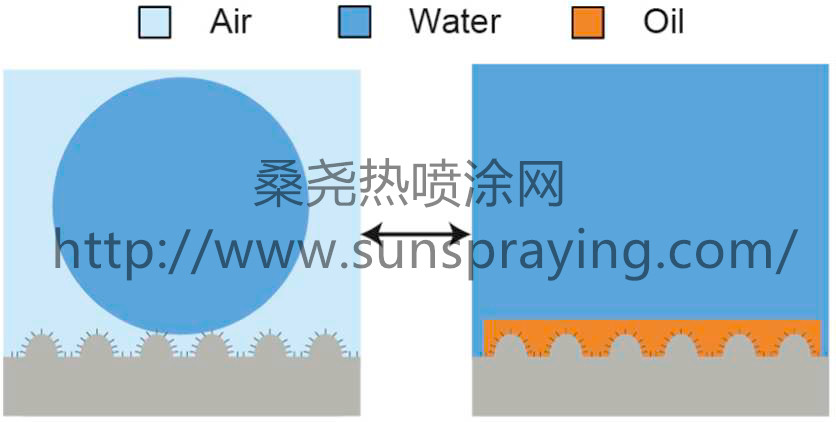

The surface properties of superhydrophobic materials are attracting increasing attention and they have been studied for potential applications such as self-cleaning , low adhesion , anti-smudging , drag-reduction , anti-icing or anti-fogging . The most useful magnitude used to classify superhydrophobic (SH) materials is the contact angle (CA) between the material surface and a water droplet; a CA>150° leads to superhydrophobic behaviour, whereas a CA between 90° and 150° corresponds to hydrophobic behaviour. Superhydrophobic (also known as superwettable) systems are hierarchical structures that result from the predominant roles of micro- and nanostructural features. These combinations generate two distinct kinds of wettability states known as Wenzel and Cassie-Baxter ; the former is defined by a homogeneous regime, while in the latter, the surface is heterogeneous and presents air pockets throughout the hierarchical structure. Furthermore, the wettability properties of superhydrophobic surfaces can switch their wetting properties under different conditions and generate several wettability states, depending on the system . In fact, water SH surfaces can switch to superoleophilic wettability which presents a new and innovative strategy to separate oil from water in complex systems. Different processes, chemicals and methods are reported in the literature which allows us to take advantage of this strategy. These includes materials such as cotton fabrics prepared via vapour phase deposition (PVD) of polyaniline and fluorinated alkyl silane ; foams modified with methyltrichlorosilane (MTCS) through a sol-gel process that permits different types of oils to be separated, such as hexane, gasoline or peanut oil ; meshes spray coated with corn cob powders that present underwater superoleophobicity ; and sponges of polyurethane (PU) where hydroxylated nanodiamonds coated with polydopamine (PDA) react with fluorocarbons and are used for separating water from oil. The capacity of different superwettable systems to switch their wettability state offers a new opportunity to apply them in different environments. A large variety of techniques and substrates are used to prepare SH coatings, such as chemical etching to generate an SH layer on aluminium substrates using lauric and hydrochloric acid as reagents; a combination of chemical etching and electrophoretic deposition can also be used to obtain SH surfaces on aluminium alloys using 1H,1H,2H,2H-perfluorodecyltriethoxysilane (FAS) as a modifying agent. In electrodeposition, a single step can be used to generate an SH coating on aluminium or 316 L stainless steel , with lauric acid and nickel chloride. In order to enhance the properties of materials or coatings, several compounds can be selected ; however, ceramics play an important role in increasing resistance to chemical agents and mechanical wear. This is the case of alumina (Al2O3): a ceramic material used in several applications because of its excellent properties, such as chemical stability, high degree of hardness and low cost. Some coatings are prepared using alumina which directly increases the hardness; and some electrochemical processes also use it to increase this property, with successful results. Here, we report a straightforward and rapid process using fatty acids to produce a stable superhydrophobic hybrid composite coating on aluminium substrate which is highly resistant to wear under environmental conditions. Furthermore, this novel superhydrophobic metal surface is highly efficient at separating of water/oil systems. The single-step process we adopt involves electrochemical deposition of ZnCl2, α-Al2O3 and lauric acid (C11H23COOH) onto commercial pure aluminium substrate. The resultant static contact angle (170°) and sliding angle (1°) are those of a superhydrophobic coating with self-cleaning properties; while chemical analysis shows that this is the result of generation of zinc laurate (Zn(C11H20COO)2) as a major compound that increases the superhydrophobic character of the coating, generating a flower-like structure 70 nm thick. Different wear tests show the coating is resistant to severe conditions, confirming its real potential against weathering, including sand and water erosion. Finally, a water/oil separation test determined 99% separation efficiency in hexane and ether petroleum systems, in a laboratory-made storage tank.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|