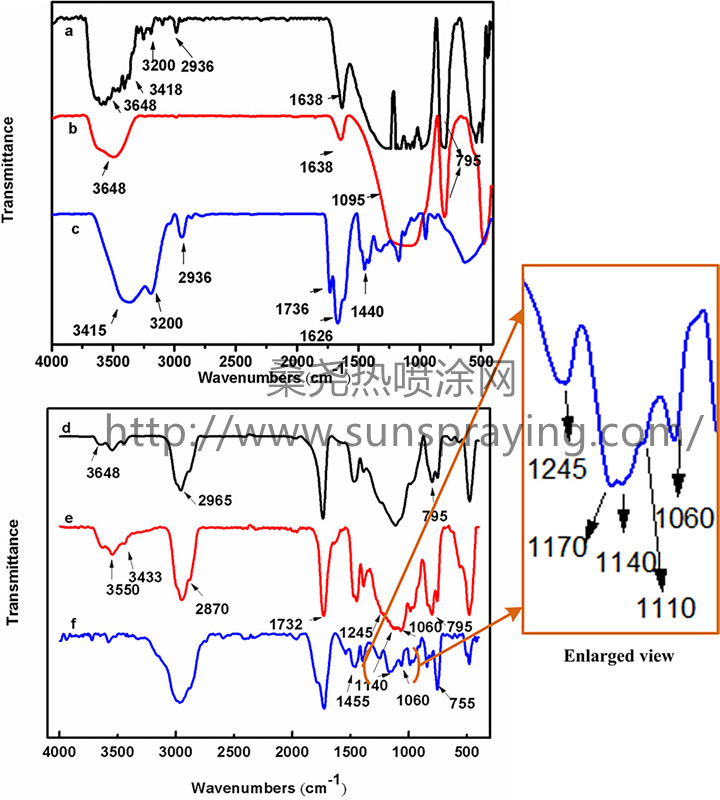

With growing attention on the environment protection, water-based inorganic/organic nanomaterial, particularly polyacrylate/silica nanoparticles hybrid emulsion becomes more attractive due to their excellent mechanical, thermal, electrical, optical properties and cheap price. However, due to their high specific surface area, surface energy and change of pH, silica nanoparticles tend to aggregate into large microparticles, even in gel if the content of silica nanoparticles was high. Without appropriate chemical modification, the maximum allowance of silica nanoparticles is usually limited to 15 wt% or less. Coatings made of such hybrid emulsion resins often exhibit low hardness, poor adhesion, and low transparency. To improve the dispersion of silica nanoparticles, Hossein Riazi et al. modified silica nanoparticles with a silane coupling agent bearing unsaturated carbon double bond to increase its hydrophobicity and enhance its ability to take part in free radical polymerization. After the polymerization, organic-inorganic hybrid particles of nanosilica encapsulated by Poly(methyl methacrylate-co-butyl acrylate) were synthesized. Christian Hübner et al. synthesized nanosized silica spheres by the Stöber method. Then the silica spheres directly were modified with a silane coupling agent. The emulsion polymerization of styrene led to hemispherical single-core-structured silica–polystyrene composite particles. Zhang et al. modified colloidal silica (R301) with water-soluble poly(ethylene glycol) monomethyl ether methacrylate (PEGMA) via hydrogen bonds, followed by dispersing modified silica (R301-PEGMA) into a waterborne UV-curable polyurethane (WUPU) via phase-inversion emulsification. However, the silica nanoparticles used in some reports were prepared with TEOS by sol-gel methods . Organic solvents are needed to dissolve TEOS during the polymerization process, which is not environmentally friendly. Moreover, the involved complicated modification processes and expensive materials also hinder their future industrial practice. Polyacrylate/silica nanoparticles hybrid emulsion (PSHE) with high silica content was produced and used in the preparation of high hardness and dry-wear-resistant coating via a facile and environment-friendly method. Specifically, the surface of alkaline silica sol nanoparticles was modified by cationic polyacrylamide (CPAM), which was then added in an emulsifier-free polymerization system comprised of methyl methacrylate (MMA) and butyl acrylate (BA). Through electrostatic attractions, hydrogen bonds, and van der Waals force, the positive charged silica nanoparticles aggregate around polyacrylate emulsion particles to improve the hardness and drywear- resistant of PSHE coating. Our results confirmed an average size of the PSHE particles only 58.6 nm. A bimodal molecular weight distribution (MWD) and consequently two different glass transition temperatures (Tg) were found in such PSHE polyacrylate resin. Due to the presence of modified silica nanoparticles, a reduced polymerization degree of MMA monomer in the aqueous phase of core emulsion leads to a decreased first Tg and the high molecular weight fraction with highly compacted molecular structure, and the improved mechanical properties of the PSHE coating. The chains of relatively low molecular weight fraction of polyacrylate move more easily during film formation, which prevents the structural voids in the coatings. Better adhesion as well as higher hardness, impact resistance, dry-wear-resistance, and thermal stability are found when compared with its pure polyacrylate emulsion (PPE) coating counterparts. Although having high silica content, the PSHE coating still retains 90% transparency rate in visible light range.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|