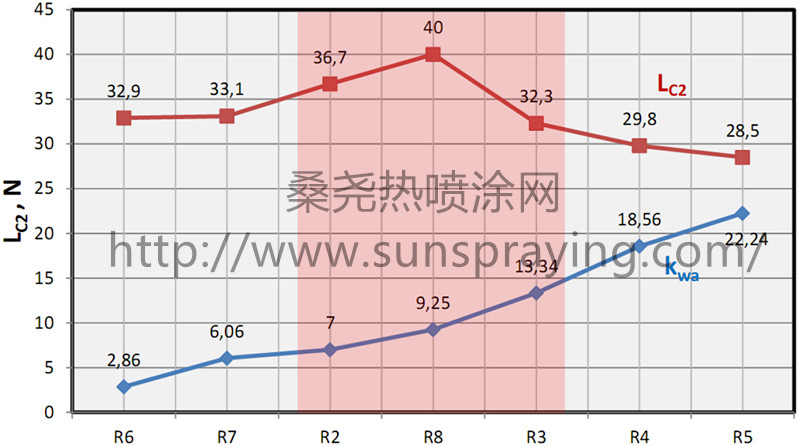

The (Zr1−x,Alx)N-based wear-resistant coatings are not as widely used as (Ti1−x,Alx)N-based coatings, but the results of a considerable number of studies prove the high performance properties of the above coatings and the good cutting properties of tools with such coatings. In particular, Ghafoor et al. considered the (Zr0.64,Al0.36)N coating. Its hardness was 36 GPa. The coating under study had a nanolabyrinthine structure with a sequence of ZrN and AlN phases. Lamni et al. studied the (Zr1−x,Alx)N coating, where 0≤x≤0.43. With the considered Al content, only the fcc NaCl-type structure was registered. With an increase in Al content, the preferred orientation (111), typical for pure ZrN, was changed to a differently directed morphology: (111), (200), and (220). With an increase in Al content, the microhardness increased from 21 to 28 GPa. Rogström et al. also considered the Zr1−xAlxN coating, but at 0.12≤x≤0.74. When x≤0.38, a cubic (Zr,Al)N phase was formed, and with an increase in Al content (x=0.70), the single-phase hexagonal structure was observed. At intermediate values of x (0.36≤x≤0.70), a mixture of the above structures was observed. It was noted that the cubic structure had higher hardness (about 35 GPa) than the hexagonal structure (about 20 GPa). With heating up to 800 °C, nitrogen re-crystallized and diffused from the cubic (Zr,Al)N phase, which led to a decrease in hardness. Meanwhile, the cubic (Zr,Al)N phase stayed stable until 1000 °C, and at higher temperatures, there was a growth of hexagonal AlN structures. At 1000 °C, in the coating with high Al content, domains with high ZrN and AlN content were formed in the hexagonal lattice, and they improved the mechanical properties of the coating. When continuing these studies, Rogström et al. found that the coatings with higher Al content were more stable. It was also found that, at the temperature of 1000 °C, Zr diffused from the wurtzite (Zr,Al) N phase and formed the cubic ZrN phase at the grain boundaries. Holec et al. considered the (Zr1−x,Alx)N system and found that the cubic structure was formed at x≤0.45, while a single wurtzite-like phase was formed at x≥0.68. Mayrhofer et al. studied the structure of the (Zr0.66,Al0.34)N coating and found that it consisted of a combination of a supersaturated cubic (Zr,Al)N solid solution with a minor portion of (semi-) coherent wurtzite AlN. In annealing at 1500 °C, the study revealed the formation of cubic domains with high Zr content and the growth of (semi-) coherent AlN domains. The loss of coherence was observed in annealing at over 1150 °C, while the hardness after annealing was 29 GPa. At the same time, after annealing, the (Zr0.68,Al0.32)N coating with the clearly oriented single-phase cubic structure had a hardness of 33 GPa, while the non-coherent wurtzite AlN structure was formed only at temperatures over 1270 °C. Franz et al. considered the (Zr1−x,Alx)N coating, where x=0.15, 0.28, and 0.58. It was found that the oxidation resistance increases with an increase in Al content, while the maximum temperature for the oxidation resistance was 800 °C. Tetragonal ZrO2 was formed during the oxidation, while Al2O3 was formed only at temperatures of over 900 °C. The highest tool life indicator was demonstrated by the coating with x=0.15, and the coating with x=0.85 showed the highest tool life indicator at high temperatures. The study involved the investigation of the effect of the thickness of the adhesion layers (0.3 and 0.7 μm) and the wear-resistant layer (2.0, 4.0, 6.0, and 8.0 μm) on the microhardness, adhesion bond strength, and performance properties of the ZrN-(Zr,Al,Si)N coatings. The scratch-test method was applied to study the adhesion bond strength to the substrate and coating failure patterns. The study revealed an effect of the coefficient kwa, determining the effect of the thicknesses of the wear-resistant and adhesion layers of the coating on the value of the critical load LC2. The study investigated the wear patterns and mechanisms for the specified coatings and the tool life of tools with these coatings in turning. An effect of the coefficient kwa which is the adhesion and wearresistant layer thickness ratio on the tool life and a difference in the wear pattern dynamics for tools with these coatings with wear-resistant layers of equal thickness and adhesion layers of different thicknesses was revealed. The study also determined the chemical and phase composition of the coatings.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|