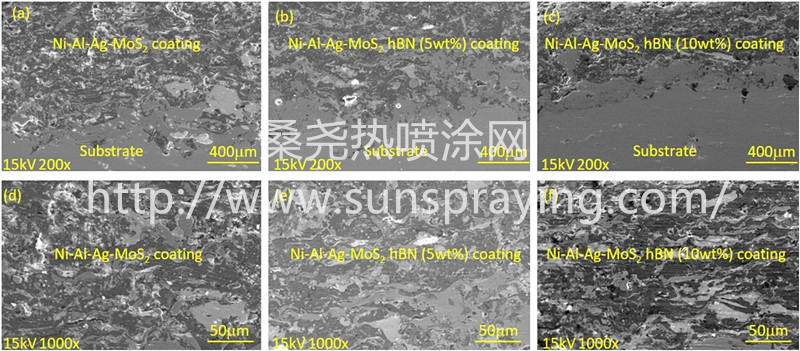

Advancements in technology has put forth the challenges for tribologists to develop solid lubricating coatings which would be able to retain low friction and wear over a wide range of temperatures for the industrial applications i.e., gas turbine, aerospace and internal combustion engines. However, it is not feasible for a single lubricant to provide effective lubrication over a regime of temperature extending from low to high temperature. Solid lubricants like graphite and Molybdenum disulphide get oxidized once the temperature exceeds above 400 °C, whereas oxides and fluorides work efficiently at high temperatures. Recently, adaptive coatings are being extensively researched because they provide effective lubrication over a broad range of temperatures. Adaptive coatings are designed in such a manner that they possess a combination of constituents which are able to provide self-lubrication via tribo-chemical reactions at elevated temperatures resulting in reduced friction and wear. These coatings have a combination of two or more solid lubricants which may also include soft noble metals. A number of studies have been conducted on the high temperature tribological behavior of coatings containing either a single solid lubricant or a combination of solid lubricants. Ling Zhong Du et al. prepared the composite coating of Ni3Al-hBN plasma spray technique and indicated that hBN plays a vital role in improving the tribological properties till addition of 10 wt%. Jie Chen et al. studied the friction and wear behavior of NiCrAlY-Ag-Mo adaptive coating deposited by plasma spray and reported the formation of silver molybdate compounds and MoO3 above 500 °C, which provided effective lubrication resulting in a decrease in friction coefficient and wear rate as compared to NiCrAlY coating. Xiaoliang Shi et al. evaluated the tribological behavior of Ni3Al based composites containing a combination of WS2, hBN and Ag from RT to 800 °C and reported that synergetic action of lubricants was beneficial in reducing the wear rate and friction coefficient. Hexagonal boron nitride has lamellar structure and it is suggested to be a better choice as a solid lubricant due to its superior adherence and ability to stabilize the tribological properties above 500 °C. Silver is also used as a solid lubricant till 500 °C as it provides low shearing strength film at the interface after being diffused to the surface due to its higher coefficient of diffusion. MoS2, a widely used solid lubricant and having a lamellar structure also forms an easy to shear lubricous film at sliding surface. During tribo testing, sulphur atoms are easily replaced by oxygen atoms and these sulphur atoms act as catalyst in the formation of silver molybdates due to tribo-chemical reactions once the temperature exceeds 500 °C. A critical review of literature presented above, suggests that a number of studies have been conducted on exploring the tribological behavior adaptive coatings containing a combination of solid lubricants, but authors could find no study on the coatings containing a combination of Ag, MoS2 and hBN as solid lubricants. Hence, the aim of the present work is to prepare NiAl based solid lubricating coatings having Ag, MoS2 and hBN and to evaluate their tribological performance by carrying out sliding wear tests from room temperature to 800 °C. The study also aims to explore the effect of varying addition of hBN on the friction and wear characteristics of these coating as well as the occurrence of any synergetic action between these lubricants in reducing the friction at elevated temperatures. Friction and wear characteristics of atmospheric plasma sprayed Ni-Al–Ag–MoS2, Ni-Al-Ag-MoS2-5 wt% hBN and Ni-Al-Ag-MoS2-10 wt% hBN coatings were examined against alumina ball at a constant load of 5 N and sliding velocity of 0.3 m/s from room temperature (RT) to 800 °C using a high temperature tribometer. The hardness of coatings was found to decrease from 182 HV0.2 to 164 HV0.2 with addition of 5 wt% hBN which further decreased to 155 HV0.2 for 10 wt% hBN. Both the friction coefficient and the wear rate were found to decrease with increasing temperature from RT to 800 °C for all the coatings. However, the coating containing 5 wt% hBN showed a consistently lower coefficient friction and wear rate in comparison to other coatings. The coefficient of friction for Ni-Al-Ag-MoS2-5 wt% hBN coating decreased from 0.5 to 0.23 with an increase in temperature from RT to 800 °C. The observed behavior has been attributed to the presence of NiO, AgMoxOy in the tribo-layer and the synergistic action of hBN which helped Ag and MoS2 in enhancing the friction and wear performance of coatings.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|