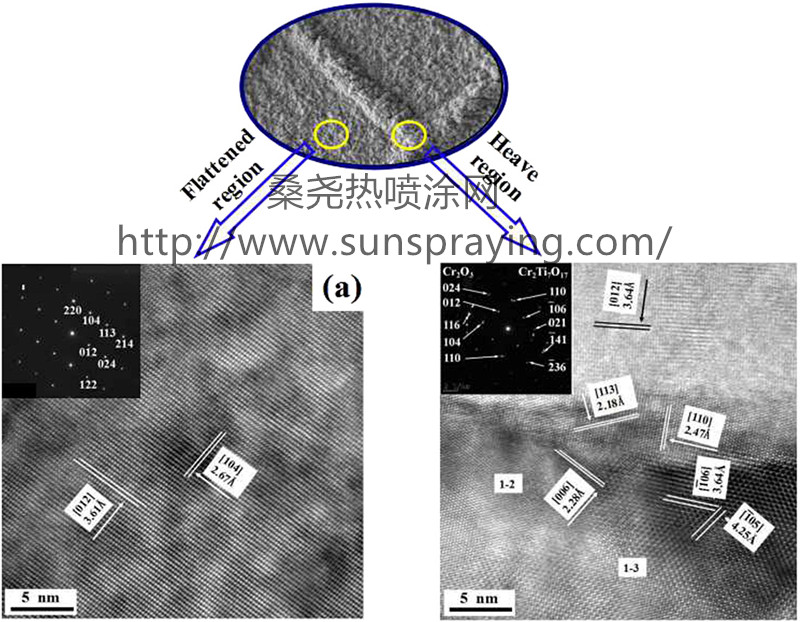

The demands of reusable solid lubricants with continuous lubricating properties from room temperature (RT) to 1000 °C or even higher temperatures become increasingly urgent with the development of high-tech industries, especially that of aerospace industry. However, tribological behavior of solid lubricants is sensitive to temperature, and conventional solid lubricants are only effective in a specific temperature range. The most widely used solid lubricants, such as graphite, molybdenum disulfide and PTFE perform well at low temperature range (RT to 400 °C), but these lubricants suffer irreversible changes under high temperatures and lose their lubricity .Moreover, the noble metals, such as gold and silver, are often added into materials to provide lubrication from RT to 500 °C. However, these metals will transfer to the material surface, which could change the microstructure and cannot provide long-term lubrication because of the large diffusion coefficient and high mobility of such metals at high temperatures. The Magnéli phases, double metal oxides, and calcium fluoride/barium fluoride could lubricate well in 500–1000 °C range, but be ineffective at low temperatures. Therefore, solid lubrication over a wide temperature range remains a great challenge for researchers. In 1990s, the “chameleon” self-adaptive coating concept was proposed and gradually became a successful approach to design selflubric coating coatings over a wide temperature range. In these coatings, multiple lubricants are contained within a hard and thermally stable matrix. The surface composition and morphology of the coatings could adapt to the changing temperature to provide effective lubrication through multiple thermally activated mechanisms, such as thermal diffusion of lubricants, formation of double metal oxides, and other environmental interactions at high temperature. PS304, which is produced using thermal plasma spray, is one of the most successful lubrication systems over awide-temperature range; this system consists of a nickel chrome alloy matrix, chrome-oxide particles, and two solid lubricants of silver and BaF2/CaF2 eutectic compound. Silver functions as a solid lubricant at a relatively lower temperature range from RT to approximately 500 °C, above which BaF2/CaF2 provides effective lubrication. The friction coefficient of the PS304 coating decreased from 0.31 to 0.23 with increasing temperature from 25 to 650 °C because of the formation of lubricating film of silver and fluorides between the wear pair. Recently, another type of “chameleon” lubricating coatings over a wide temperature range, including Mo2N/MoS2/Ag and YSZ/Ag/Mo/ MoS2, has been intensively investigated. Similarly, MoS2 and Ag function as low-temperature lubricants. At high temperature above 500 °C, chemical reactions occur among the Mo, Ag, and O elements, and lead to the formation of double metal oxides, such as AgMoxOy, that exhibit relatively low friction coefficient. Thus, both coatings mentioned can maintain low friction coefficient from 25 to 600 °C. Although great progress has been achieved on self-lubricating coatings over a wide temperature range, several problems still exist. Among them is the retention of lubricating property of coatings subjected to multiple temperature cycles. Under high temperature, thermally activated physical and chemical interactions, such as thermal diffusion of noble metals, oxidation of low-temperature lubricants, and formation of double metal oxides, occur on the coating surface to provide lubricating properties. However, most of these interactions are irreversible, and several reaction products (noble metals, oxides) are abrasive, which increases friction and wear when cycling at low temperatures. Muratore reported multilayered YSZ-Ag-Mo coatings (four layers)with TiN diffusion barriers interspersed between layers to control diffusion of Ag; the friction coefficient of the coatings showed no evident change, and wear life was prolonged over two thermal cycles from 25 to 500 °C. The development of new coatings that can be used at temperatures above 800 °C is another concern that has to be addressed .Majority of research works focus on the high-temperature friction and wear behavior of “chameleon” coatings below 800 °C, which is far behind the requirements for lubricating coatings of hot parts working at higher temperatures such as 1000 °C. The chromium oxide coatings are deposited on Ni-based high-temperature alloy substrates through an arc ion plating systemand then annealed at 1000 °C in air for 2 h. During annealing process, Ti and Cr atoms in the substrate diffuse to coating surface and lead to the formation of amesh-like heave structure comprised of Cr2O3 and Cr2Ti7O17 phases. The annealed coating exhibits the excellent self-lubricating behavior with friction coefficients below 0.3 from 25 to 1000 °C. Friction coefficients show no evident change even in five thermal cycles, showing a great potential as self-lubricating coating operated in a wide temperature range. While the mesh-like heave structure is damaged by friction, Ti and Cr atoms diffusion could continuously supplement the heave structure at the damaged locations at high temperature, enduing the mesh-like heave structure with the self-healing ability.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|