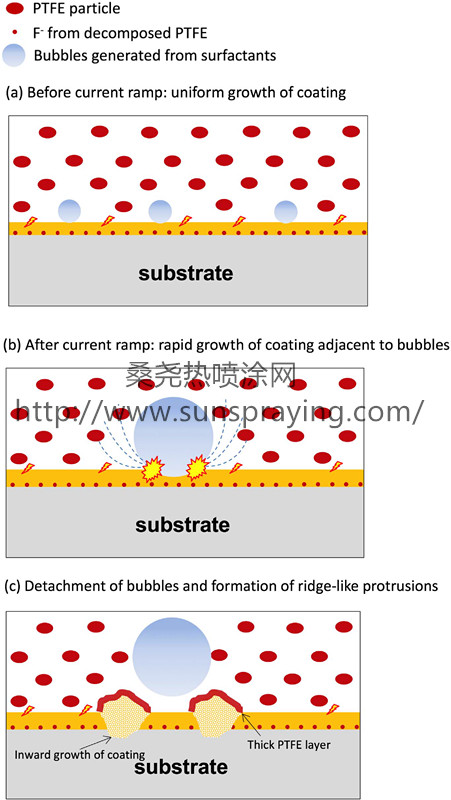

Plasma electrolytic oxidation (PEO) is one of the promising surface treatment processes, which can produce electrically insulating ceramiclike coatings on light metals and their alloys (Al, Mg and Ti). The properties of PEO coatings mainly depend on electrolyte and electrical parameters, where the composition and concentration of the electrolyte play decisive role in dominating the thickness, phase composition and properties of the layer. Nevertheless, due to relatively high porosity and limited range of phase compositions, PEO coatings are still not capable of providing long-term corrosion and wear protection for Mg alloys. Latest trend in the field of PEO is a highly active topic, including in situ incorporation of solid particles to tune and improve microstructure, phase composition and properties of the coatings. In terms of wear performance, most of the studies only focus on increasing the hardness, thickness and compactness of the coating, while the friction coefficient between the layer and its counterpart is still very high, which leads to early failure of the coating and can be very critical for practical application. Therefore, introduction of particles with lubrication properties is of significant importance to overcome the obstacle for Mg alloys to be used for industrial application. PTFE, MoS2 and graphite particles have been incorporated into PEO coated Al and Ti alloys, while such work is rarely observed for Mg alloy. Due to cost effectiveness and high chemical stability, PTFE particles are frequently-used for enhancing the tribological performance of PEO coatings by post-treatment, e.g. low vacuum infiltration or electrophoretic deposition. Normally, after incorporating PTFE particles into the conventional PEO coatings, friction coefficient between the layer and its counterpart can decrease from 0.5–0.7 to below 0.2 . Introduction of PTFE particles in ex-situ incorporation regime is restricted due to their physical property, since it is always a challenge to disperse the particles uniformly in the aqueous solution as a result of its super-hydrophobicity ability. Moreover the low melting point (327 °C) is another issue for the particles to achieve in-situ incorporation into the coating due to the appearance of high-intensity discharges during PEO treatment. In the present work, surfactants are utilized to improve dispersion stability of the particles and relatively low energy input is applied to achieve in-situ incorporation. The underlying mechanism is that the hydrophobic groups of the surfactants can adsorb on the particle surface, leading to formation of a hydrated shell on the particle. Thus it can change the surface polarity and significantly reduce the surface tension of the hydrophobic PTFE particle. Consequently, self-lubricating PTFE containing,PEO coatings have been fabricated via in-situ incorporation regime. Due to inert incorporation of PTFE particles, ultra-low friction coefficient between the coating and its counterpart could be achieved for PEO coated Mg alloy. The uptake mechanisms of the particles are also proposed herein. Self-lubricating plasma electrolytic oxidation (PEO) coatings have been fabricated on AZ91 magnesium alloy via in-situ incorporation of PTFE particles. Surfactants are used to improve dispersion stability of the particles in aqueous solution and relatively low energy input is applied to ensure the particles are inertly incorporated into the coating. It was found that the porous layer has been sealed significantly and PTFE-enriched ridge-like protrusions can be obtained on the coating surface after sufficient treatment time. 3D surface micro-topography was reconstructed to disclose the uptake of the particles and wear mechanisms of the coatings. The particlecontaining protrusions can act as lubricant reservoirs, leading to ultra-low and stable friction coefficient between the coating and its counterpart during entire dry sliding wear test. The formation of the ridge-like protrusions is related to micro-sized gas bubbles adherence to the coating surface due to high viscosity of the electrolyte. As a consequence, the intensity of electric field at the edge of the bubbles increases, which could facilitate rapid sintering and accumulation of PTFE particles at the electrolyte/gas/coating interface.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|