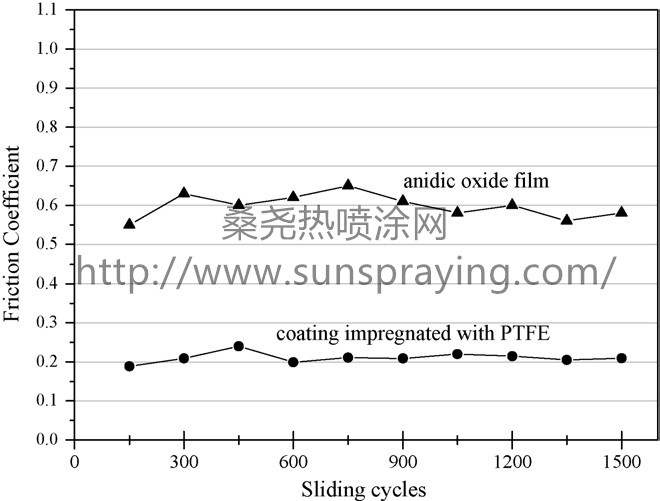

Anodicoxidation treatment, when applied to aluminum and its alloys, can increase the surface hardness and resistance to abrasive wear. Furthermore, it can form surface self-lubricating composites when adding some appropriate lubricants to those pores of anodized film such as MoS2 or PTFE. Various methods have been studied in order to improve friction performance of aluminum anodic oxide coating, such as physical impregnation, duplex anodization, sputter-deposition, electrophoretic-deposition and Teflon technology. The methods of physical impregnation and electrophoretic deposition have been used widely for their convenient and economic character. However, their filling efficients are both low since the pores of anodized film on aluminum are nano-size. Duplex anodization is the method to deposit solid lubricant, such as MoS2, in the pores of anodized film on aluminum by reanodizing in (NH4)2MoS4 solution. Some researchers think the deposited products were sulphides of Mo rather than single MoS2, which decrease the self-lubricating properties of the materials. Sputter-deposition films of MoS2 have been used as lubricants for space applications. Since its high cost, its applications in normal industry, especial civil industry, are not available. Teflon technologymay lead to the distortion of the samples because it uses the force of press, and it also restricted by the shape of the samples and cannot be available in complex samples and small samples. A self-lubricating anodic film with the properties of antiattrition and abrasion resistance was prepared on aluminum. The fabricating process contains: (1) oxidation in a electrolyte of phosphoric acid and some additives; (2) ultrasonic impregnation in a PTFE latex; (3) heat treatment on the film impregnated with PTFE. The macroporous and thick anodic oxide film were obtained by anodizing and its structure depends on the anodizing temperature and current density greatly. More PTFE can be entered the pores of anodic film while the hardness will decrease after long-time ultrasonic impregnation. The appropriatetime is 5 min within which the surface hardness varies little. The sequent heat treatment can increase the coating hardness greatly. Pin-on-plate reciprocating tribological tests reveal a significant reduction in the frictional coefficient and wear with this preparation method.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|