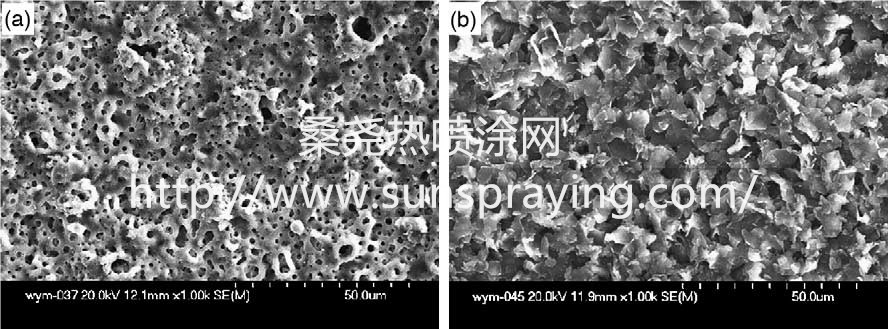

Microarc oxidation coatings were fabricated on Ti6Al4V alloy in NaAlO2 containing solution. Microstructure and adhesion propertie of the coatings were evaluated. For antifriction purpose, a novel duplex coating of microarc oxidation combined with spraying graphite process was developed. The results show that the microarc oxidation coating with 20 mm thickness is compact and uniform in the inner layer, while porous in the surface layer. The coating has high adhesion strength of about 110 MPa to the substrate. The novel duplex coating exhibits good antifriction property, registering friction coefficient of 0.12, which is 5 times lower than that of the microarc oxidation coating sliding in the similar condition. The good tribological property is attributed to the specially designed duplex structure, the coating adhering strongly to the substrate and serving as the underlying loading layer and the graphite layer on top of it working as solid lubricant. Among the involving oxidation methods, a novel method based on thermal oxidation (TO) has been successfully developed. Essentially, the modified technique is a thermochemical process, which is usually carried out in a controlled atmosphere containing oxygen as well as nitrogen at 600–650℃ for 50– 100h, and provides the benefits of both the formation of a thin rutile oxide layer (2 mm) and a oxygen diffusion zone (20 mm). Compared with the conventional TO treatment, newly developed TO process can effectively harden titanium alloys without causing scaling or surface damage . However, this method is still subjected to long treatment time and the thick oxygen diffusion zone is susceptible to deteriorate the mechanical properties of the bulk substrate. Anodizing of titanium only produces a very thin coating (typically 0–200 nm) in acidic, neutral, and mildly basic solutions, though anodizing in strongly alkaline solutions can produce coatings up to several microns. However, the anodizing coatings still are too thin to provide effective protection of wear and corrosion, therefore, commonly applied to decorative purpose. A novel anodizing method enhanced by sparking discharge, namely microarc oxidation (MAO), characterized by high productivity, economic efficiency and ecological friendly, especially, enabling to achieve the thicker ceramic coatings of excellent properties: high hardness, good wear resistance and excellent bonding strength with the substrate, has been significantly focused on forming ceramic coatings on titanium alloys to improve corrosion resistance and wear resistance. However, till now, the relations of microstructure and properties are not well understood, specially, the antifriction issue of microarc oxidation coatings is not well resolved. Microarc oxidation coatings were formed successfully on Ti6Al4V alloy in a NaAlO2 containing solution. The microarc oxidation coating with 20 mm thickness is compact, uniform in the inner layer, porous in the surface layer. The coating has high adhesion strength to the substrate (about 110 MPa). The novel duplex coating of microarc oxidation combined with spraying graphite process exhibits good antifriction property, registering friction coefficient of 0.12, which is 5 times lower than that of the microarc oxidation coating sliding in the similar condition. The good tribological property is attributed to the specially designed duplex structure, the microarc oxidation ceramic coating serving as underlying loading layer and graphite layer on top of it working as solid lubricant.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|