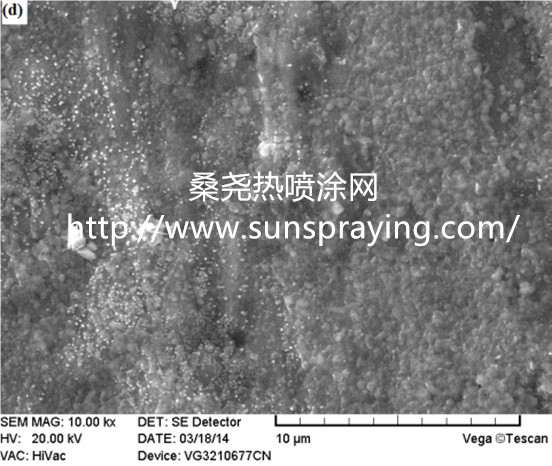

High-temperature self-lubricant coating which has well mechanical and tribological properties at 25~1000℃ was a hotspot in the industry. Recently, several lubricant coatings were researched. Where, in the solid lubricant coatings, the silver and barium-calcium fluoride eutectic was added to the binder and act as high-temperature lubricants. The composite coatings of PM212/PS212, PS300, PS400 were composed of a good matrix (NiCr-Cr3C2, or NiCr-Cr2O3) and Ag with BaF2·CaF2 eutectic solid lubricants. Research of the coatings indicates that the lubricious glaze formed in the surface of coatings to achieve low friction and wear rate of a high wide temperature range. However, at room temperature, the wear rate of the coatings is even high that the lubricious glaze was destroyed. Above 800℃, the oxidation and the decline of the mechanical property degraded its wear resistance. So, in order to obtain optimal friction property of lubricant coatings at wide temperature range, the NiCoCrAlY-WSe2-BaF2·CaF2 coatings were fabricated on the substrates of ASTM4145 alloy steel. The results demonstrate that the TC1 coatings have better self-lubricating properties at 500℃, and the TC2 coatings have the better performance at friction and wear-resistant properties at 800℃. When the temperature is low (such as 500℃), the WSe2 acts as the lubricant phase in the coatings, TC1 coating has more, so it has a low average friction coefficient at 500℃. When the temperature comes to 800℃, the WSe2 is disabled; the BaF2 and CaF2 play the role instead. The phase changes on the surfaces of TC1 coatings at 800℃, they are the oxidant, and the film is on the surface of coatings so as to wear easily. The debris on the sliding surfaces was effected on the friction pair, and the structure characteristic of the coatings. The self-lubricant property of the NiCoCrAlY-WSe2-BaF2·CaF2 composite coatings in a wide temperature was consisted of BaF2·CaF2 and WSe2. At the lower temperature, the WSe2 act as solid lubricants. At high temperature, the TC2 coating has the highest friction coefficient at 500℃. At 800℃, the TC2 coating has the lowest friction coefficient. Where, the new production, BaCrO4, provides an excellent tribological property at high temperature. Moreover, the compactness of the coatings at high temperature (at 800℃) is bad contrast to them at 500℃for the decomposition of WSe2. So, there are some pores in the coatings.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|