Titaniumalloys exhibit ever increasing interest in the fields of automotive,medical and offshore engineering, because of their high strength-to-weight, excellent corrosion resistance and biocompatibility. However, the poor tribological behavior caused by high and unstable friction coefficient, severe adhesive wear and a strong tendency to seize have seriously restricted extensive applications of titanium in various industry sectors. The coatings mainly composed of nanostructured TiO2 were deposited on Ti6Al4Valloy by microarc oxidation (MAO). The duplex coatings of microarc oxidation combined with spraying graphite process were fabricated for the antifriction purpose. Thetribological properties of unpolished, polished and duplex coating against steel under dry friction conditions were examined. As a surface modification technique, microarc oxidation (MAO) is an effective and economical method to deposit ceramic coatings on titanium alloys for wear resistance protection. As a result of polish

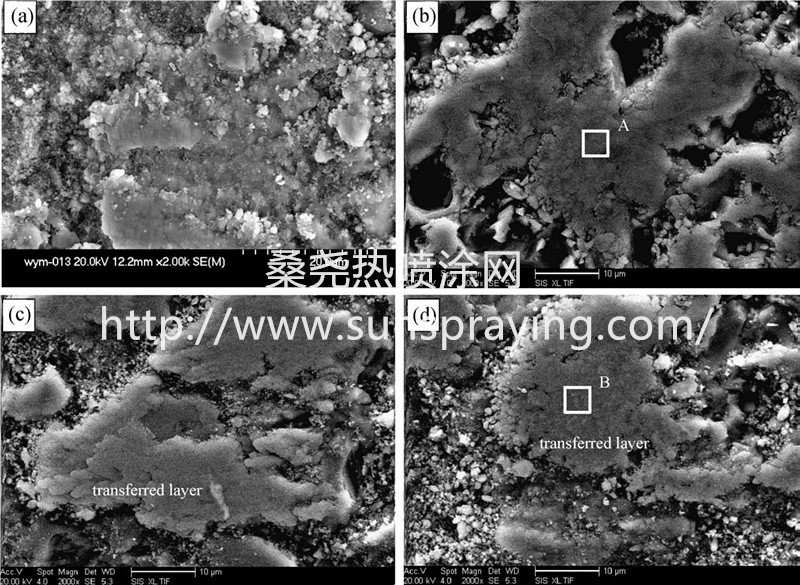

treatment, the surface becomes smooth at the site of the original ceramic island.However, some local pores were still retained and dispersed in the outer smooth surface. More interestingly, the porous feature of the microarc oxidation coating opens a good way to introduce solid lubricant into micropores or depositing on the surface of coating. The emulsive graphite lubricant was introduced into the porous surface of the unpolished microarc oxidation coating using a selfmade spraying gun with four atmosphere pressures, followed by solidification at 180℃ for 15min. It seems that the nano-scale TiO2 grains in black circular shape disperse among the boundary of light gray AlPO4 grains. The fact that AlPO4 phase is dominant in the analyzed area is in agreement with the cutting way of TEM specimen, which was taken from the outer layer of the coating. Under the dry sliding conditions of this study, for uncoated Ti6Al4V, the long-term friction coefficient remains a high value of about 0.5–0.6. The dominant wear mechanisms for the untreated Ti6Al4V sliding against steel are extensive adhesive and abrasive wear. The coatings mainly composed of nanocrystalline TiO2 were deposited on Ti6Al4V alloy by microarc oxidation (MAO). The duplex coatings of microrc oxidation combined with spraying graphite process were fabricated for the antifriction purpose. The tribological properties of unpolished, polished and duplex coating against steel under dry friction conditions were examined. It is found that antifriction property of polished microarc oxidation coating is superior to that of unpolished one. The improvement is attributed to the low surface roughness and the nanocrystalline structure of coatings. The duplex coating exhibits best antifriction property, registering a lower and steady friction coefficient of 0.12 than that of the polished microarc oxidation coating sliding in the similar condition. The good tribological property is attributed to the specially designed duplex structure, the coating adhering strongly to the substrate and serving as the underlying load-supporting underlayer and the graphite layer on top of it working as solid lubricant.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|