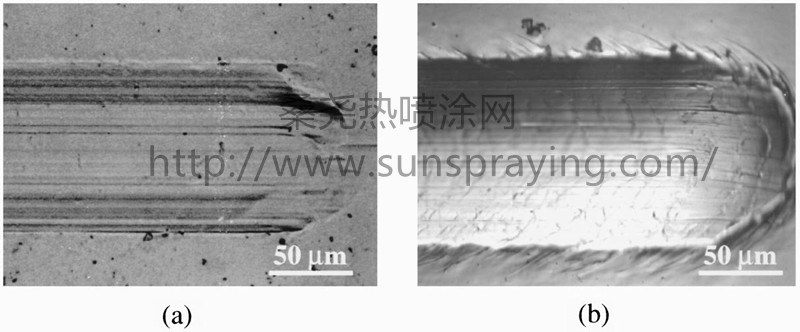

The chameleon's ability to change skin color depending on environment to increase its chances of surviving served as an inspiration in the development of self-adaptive supertough wear-resistant coatings. Surface chemistry, structure and mechanical properties of these thin (0.5 mm) coatings reversibly change with applied load and environment, providing the best wear protection. Coating designs developed in-house are reviewed together with a critical analysis of design reports in the literature. `Chameleon' coatings were prepared using novel nanocomposite structures, consisting of crystalline carbides, diamond-like carbon (DLC), and transition metal dichalcogenides. Various mechanisms were activated to achieve surface self-adaptation and supertough characteristics. They included: transition of mechanical response from hard and rigid to quasi plastic by grain boundary sliding at loads above the elastic limit; friction induced sp3!sp2 phase transition of the DLC phase; re-crystallization and reorientation of the dichalcogenide phase; change of surface chemistry and structure from amorphous carbon in humid air to hexagonal dichalcogenide in dry nitrogen and vacuum; and sealing the dichalcogenide phase to prevent oxidation. These mechanisms were demonstrated using WC/DLC, TiC/DLC, and WC/DLC/WS2 coatings. The hardness of WC/DLC and TiC/DLC composites was between 27±32 GPa and scratch toughness was 4±5 fold above that of nanocrystalline carbides. The WC/DLC/WS2 composites survived millions of sliding cycles in vacuum and air under 500±1000 MPa loading, and exhibited excellent friction recovery in humid$dry environmental cycling. Their friction coef®cients were about 0.1 in humid air, 0.03 in vacuum, and as low as 0.007 in dry nitrogen. The proposed `chameleon' concept can dramatically increase wear-resistant coating applicability, durability, and reliability. Recently, there has been considerable progress in the development of superhard nanocomposite structures. However, their designs do not provide mechanisms for super-tough properties, since they are, in principle, directed toward suppression of plastic deformation. While high hardness is an important attribute of wear-resistant coatings, high toughness and low friction may have similar or greater importance. In order to improve hard coating toughness, some ductility should be introduced, which ideally should be activated at loads above the elastic strength limit. Thus, it is desirable to have a dual-property material, which is ordinarily very hard, but switches its behavior to ductile at extreme loading to prevent brittle fracture. Since dislocation motion is prohibited in nanocomposite structures, alternative mechanisms for ductility should be sought. Grain boundary sliding is one of the most promising due to the large volume of boundaries available in nanocomposites.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|