It is well known that when two or more solid lubricants are incorporated, an unexpected synergetic lubricating effect can be observed, which is superior to any one of the single lubricants. Examples include mixture of graphite and calcium fluoride, and MoS2 and PbO. The application of a mixture of inorganic solid lubricants is one of promising approaches to fabricate high temperature self-lubricating composites. Zabinski et al. prepared the composite films of PbO–MoS2 with excellent lubricating properties at elevated temperatures by pulsed laser deposition. Tian reported the lower friction coefficients and wear rates of MoS2 + CrO3 compared with MoS2 alone. Lu realized a synergetic effect of silver and CeF3 on reducing friction at 700 ◦C and the corresponding friction coefficientwas as lowas 0.11. Furthermore, these authors also proved synergetic lubricating effect of CeF3 and graphite. Xiong revealed the self-lubricating properties of the combination of LaF3 and MoS2 was superior to LaF3 or MoS2 alone. The friction coefficients show that friction coefficients and wear rates of Ni–Cr–W–Fe–C–MoS2 composite were much lower than those of Ni–Cr–W–Fe–C and Ni–Cr–W–Fe–MoS2. For

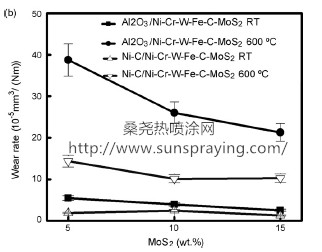

the single-lubricant composite (MoS2), most of molybdenum disulfides were decomposed during processing and the remaining was insufficient to form an intact lubricating film. The corresponding friction coefficient was relatively high at room temperature, but the high-temperature lubricating properties were still excellent as a result of lubricating effect of CrxSx+1. In contrast, graphite possessed excellent lubricating properties at room temperature, but degraded at elevated temperature due to oxidation. Since molybdenum disulfide and graphite lubricate effectively at elevated temperature and room temperature, respectively, lubrication over a wide temperature range can be realized by combining graphite and sulfide. Friction coefficients and wear rates were kept constant, despite with the increase of molybdenum disulfide content at room temperature, while friction coefficients and wear rates decreased with the increase of molybdenum disulfide content at 600◦C. This indicated that molybdenum disulfide was more effective at elevated temperature than at room temperature. The friction coefficient was kept almost constant at room temperature, which corresponds to the certain graphite amount.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|