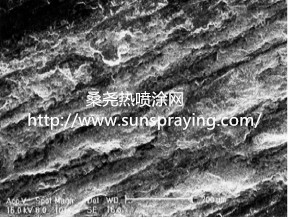

Electroless plating is one of the methods by which composite coatings can be produced. Two types of electroless coating have been investigated including Ni–P and Ni–P–Al2O3 coatings.These coatings were applied on AISI 1045 steel discs by electroless deposition process and then they were heat treated at 200, 400 and 600 ℃ for 1 h. Co-deposition of alumina particles within Ni–P coating matrix changes the roughness and the surface morphology of composite deposits from a smooth state in Ni–P coatings to a non-smooth state with the nodular appearance in Ni–P–Al2O3 composite coatings. The hardness and wear resistance of Ni–P electroless coating have been modified by co-deposition of alumina particles within Ni–P matrix, whereas maximum hardness and wear resistance were achieved in heat treated coating at about 400 ◦C.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|