Recently, the increasing potential for the use of Cr2O3 ceramic coatings as wear resistant coatings in a variety of aerospace and automobile applications has focused great attention on these materials. The plasma-spray methodis most widely used to produce a considerable variety of Cr2O3-based ceramic coatings, which show favorable tribological behavior: high anti-wear resistance and ease of lubrication owing to the oil storage of the pores in the coating. However, plasma-spray processing parameters, such as feed material and process operating parameters greatly affect the coating quality, such as microstructure and chemical composition distribution, hardness, bonding strength and toughness.

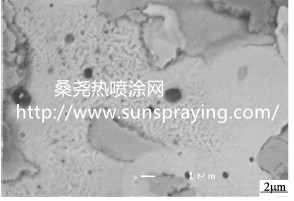

The friction and wear characteristics of plasma-spraying Cr2O3 coatings are significantly affected by the compo-sitional and microstructural features, such as microcracks, porosity, morphology and distribution of additions. The wear mechanisms of Cr2O3 ceramic coatings are complicated but can be classified by one of three dominant processes: surface crack propagation, plastic deformation and smooth film transfer. With the change of wear conditions, such as load, sliding speed and temperature, etc. the transition from fracture-dominated wear to deformation-dominated wear is often accompanied by a great change in both friction and wear. To date, only a limited amount of experiments has been done on lubrication of Cr2O3 ceramic coating. These studies utilized several kinds of solid lubricants (CaF2, BaF2 or silver) as additives or a well-adhering soft metallic coating as a boundary film. Improved tribological characteristics of Cr2O3 ceramic coatings at elevated temperature were reported through solid lubrication method. Spray drying of a Cr2O3–CaF2 powder blend allows to obtain a homogeneous distribution of the lubricant in the composite coatings plasma-sprayed with these agglomerates. It was proven that optimizedparameters for plasma-spraying the pure Cr2O3 are also suitable to spray the Cr2O3–CaF2 composite coatings.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|