As a kind of representative metal-based protective coating,MCrAlY (M is Nickel, cobalt, or a combination of the two) alloy coatings are of special significance in preventing the hot parts such as rotary and static blades of turbine from hot corrosion and high temperature oxidation. Usually, high velocity oxy-fuel (HVOF) spraying technology is applicable to preparing MCrAlY coatings that are sensitive to oxidation, because HVOF spraying works well at low flame temperature, low dwell time and high flame velocity thereby providing as-sprayed coatings with low porosity, good adhesion to substrate and desired microstructure.

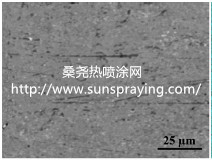

Agglomerated and sintered CoCrAlYTaCSiAAl2O3 powder wasused to prepare MMC coating by HVOF spraying. Spherical CoCrAlTaCSiAAl2O3 powder fabricated by agglomerating and sintering technology is suitable for depositing MMC coating on Ni-based alloy substrate by HVOF spraying.As-sprayed CoCrAlYTaCSiAAl2O3 coating exhibits a dense microstructure and contains homogenously distributed Al2O3 particles with a size of several micrometers. HVOF-sprayed CoCrAlYTaCSiAAl2O3 coating exhibits enhanced mechanical properties as well as good oxidation resistance and wear resistance at elevated temperatures up to 1000℃, showing promising potential as the protective coating of Ni-based alloy hot parts.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|