Deposition of hard thin films with a few microns in thickness is a common technology to improve the performance of tools, dies, and molds for many different applications . Starting with thermally activated chemical vapor deposition (CVD), different methods have been developed including plasma-assisted physical vapor deposition (PVD) , plasma-assisted chemical vapor deposition (PACVD) and laser-assisted methods like pulsed laser deposition (PLD). The importance of wear-resistant hard coatings is given by the following facts. About 90% of all indexable inserts for metal cutting, based on cemented carbide substrates, are coated for wear protection by CVD or PVD techniques, with PVD being used in about 25% of the cases. The important issue for the future is not which deposition technology is used, but instead which properties can be achieved at which production cost. This is where the need for microstructural design enters the field.

Hard coatings prepared by various deposition techniques and conditions exhibit the widest variety of microstructures among materials in terms of grain size, crystallographic orientation, lattice defects, texture, and surface morphology as well as phase composition. The recent review by Petrov et al. clearly shows the microstructural evolution during film growth. The film exhibits a columnar microstructure with elongated grains, which is the typical product of today’s coating processes of ceramic materials. For characterization of the ion bombardment conditions, which are commonly used to adjust the film microstructure during plasma-assisted growth, the incident ion/metal flux ratio Jion/Jme and ion energy Eionare used as main parameters. Jion and Eion can be determined using Langmuir-probe measurements following the procedures described in Ref.

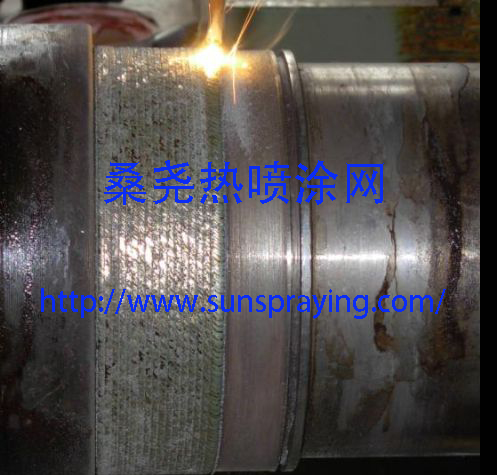

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|