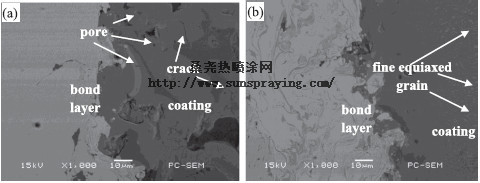

A lot of hydraulic equipments such as turbine blades can easily happen wear damage which greatly shorten their service life.Ceramic coatings which have excellent physical and chemical properties can be applied to the surface of these hydrodynamic devices to effectively improve their wear resistance. Among the processes employed for coating, plasma spraying has become popular for many applications. However, the coating obtained by plasma spraying is prone to some defects, such as high porosity, lamellar structure and inadequate adhesion. Laser remelting, a surface strengthening technology, has been thought to be an efficient way to solve those defects and improve the quality of the plasma spaying coating. Al2O3 with high hardness is one of the most promising materials for tribological application. It has been reported that Al2O3 coating exhibits excellent wear resistant. However, the brittleness of Al2O3 coating is usually unsatisfactory, which largely limited its wide application. TiO2 is also widely used as ceramic material for coating. The addition of TiO2 into Al2O3 coating was found to be advantageous for an increase of the wear resistance of the coating, in which TiO2 has a low melting point but strong adhesion can be partially embedded into the pores between Al2O3 particles. Therefore, the Al2O3-TiO2 ceramic coating obtained by mixing TiO2 and Al2O3 powder was characterized low porosity, high strength and good wear resistance. The Al2O3-40%TiO2 coating fabricated by plasma spraying on carbon steel substrate were remelted by laser, and the effect of laser remelting on microstructure and wear resistance of plasma sprayed Al2O3-40%TiO2 coating were studied. The microstructure and phase composition of plasma sprayed and laser remelted coatings were analyzed using scanning election microscopy (SEM), energy disperse spectroscopy (EDS) and X-ray diffraction (XRD). The micro-hardness and adhesion strength of two coatings were measured using micro-hardness tester and electronic universal tensile testing machine. The wear resistance of two coatings was tested through a slurry rubber wheel abrasion test machine, and the wear behaviour was also studied by SEM. The results show that metastable phase γ-Al2O3 in coating is completely transformed into stable phase α- Al2O3 after laser remelting. The laser remelted coating becomes much denser, and then its microhardness and adhesion strength have been greatly improved. The laser remelted coating exhibits better wear resistance compared to the plasma-sprayed coating, and the main wear mechanism responsible for wear was microcrack and fracture wear.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|