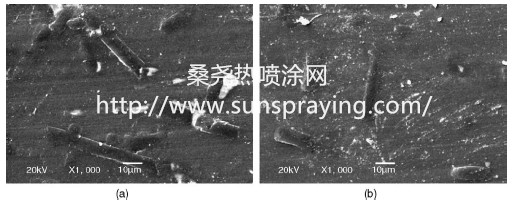

Polymer coatings have many good properties such as surface decoration, corrosion protection, low noise, insulation and wear resistance, so they are used widely in many fields of aviation, spaceflight, medicine and so on. Many kinds of preparation technologies such as electrostatic powder coating, electrostatic fluidized-bed coating, painting, and flame spraying have been widely used in the preparation of various polymer coatings. Of those methods, flame spraying has been attracting increased attention, owing to the advantages of cost-effective, low-pollution and physically portable process for thermoplastics. Therefore, flame spraying has been used to prepare various kinds of polymeric coatings such as polyetheretherketone (PEEK), polyphenylenesulfide (PPS) [5,6], polyethylene (PE), PE copolymers, polymethylmethacrylate (PMMA), polytetrafluorethylene (PTFE), and nylons. However, most of the reported work in this area is confined to the physical properties or the friction and wear behaviors of the flamesprayed neat polymer coating little has been focused on the tribological investigation of flame-sprayed polymer-based composite coatings filled with fillers. This is hindering the potential of various fillers in the tribological application of flamesprayed polymer-based composite coatings. At the same time, most of the researches on the friction and wear behaviors of bulk polymer materials and polymer coatings are limited to dry sliding conditions. In other words, little is available on the tribological study of polymeric materials under water lubrication or in aqueous medium, though it is of considerable importance in terms of the tribological application of polymeric materials in engineering. Carbon fiber reinforced polyphenylene sulphide (PPS) composite coatings (the mass fraction of the carbon fiber varied from 1 to 5 wt%) were prepared by flame spraying. The microstructure and physical properties of the composite coating were studied. The friction and wear characteristics of the PPS coating and carbon fiber reinforced PPS composite coating under dry- and water-lubricated sliding against stainless steel were comparatively investigated using a block-ring tester. The composite coatings showed lower friction coefficient and higher wear rate than pure PPS coatings under dry sliding. Under water-lubricated condition, the composite coatings showed better wear resistance than under dry.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|