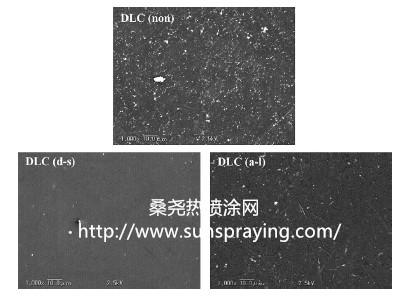

Although the use of water has many advantages, the low lubricity of water has to be solved to develop the reliable water hydraulic systems. Therefore, tribology is the key technology to overcome the problem of water. Some inorganic materials or coatings on metal surfaces are known to have a good lubricity under water lubrication. For example, silicon nitride (Si3N4) and silicon carbide (SiC) show low friction in water environments. In spite of having good lubricity underwater lubrication, silicon nitride or silicon carbide cannot be applied to the commercial power systems due to the cost or their low machinability. Diamond-like-carbon (DLC) is known as a low-cost coating durable not only for under dry condition but also for under water lubrication. The authors have already reported that the DLC-coating showed low friction coefficient and sliding speed dependency of friction coefficient is very small under water lubrication. There have been many reports on DLC-coating because it has unique properties, such as chemical inertness, mechanical, tribological and optical properties. It has been knownthat small particles called “droplets” are occasionally observed on the surface of DLC-coatings. The degree of droplets formation varies depending on the deposition method. Especially, it is unavoidable in case of sputtering. Some experiments show that generation of droplets can be controlled using a filter .However, degree of droplets formation is not always same even under the same condition and same deposition method, and in addition, it is unpredictable. From the tribological point of view, effect of the droplets should be clarified to maintain good lubricity. To achieve a hydraulic power system, it is important to control tribology because water has a lack of lubricity. Therefore, coated surface is necessary under water lubrication. Diamond-like-carbon (DLC)-coating is known as a useful material because of its high hardness and low friction, therefore it can be used as a coating durable for the water lubrication. Deposition methods of DLC-coating are developed in various ways. Particles called “droplets” are observed on the surface of DLC-coating depends on deposition methods and it can affect friction and wear properties. In this study, DLC-coating was prepared using a multi-cathode unbalanced magnetron sputtering (UBMS) system. The surface was polished with diamond slurry solution and aero lap to remove droplets. DLC-coatings were evaluated by tribo-tests before and after polishing. It is considered that some surface modification occurred. Moreover, the results of tribotests show that friction coefficients became lower and more stable than before polishing. Although partial delamination was observed after tribo-tests without polishing, no appreciable wear was observed after polishing.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|