Plasma spraying is a thermal spray process in which coating materials in powder form are simultaneously heated and accelerated in a gas kept in a plasma state using an electric arc.The coating is built-up on the substrate by the impingement of the molten or semi-molten particles, which flatten after impact and solidify quickly, forming a layer. Deposition of such multiple layers yields a coating of desired thickness. These thick coatings are used in variety of applications like automotive systems, boiler components, power generation equipment, chemical process equipment, aircraft engines, pulp and paper processing equipment, bridges, rollers and electric arc furnace (EAF) electrodes in steel mills, concrete reinforcements, orthopaedics and dental prostheses, land-based and marine turbines, ships, etc.From the last decade, ceramic composites material reinforced with CNT and multiwalled carbon nanotube (MWCNT) is gaining popularity. These nanotubes can also be incorporated in thermally sprayed coatings to improve their mechanical, electrical, electronic properties.For example, when MWCNT is added to alumina as reinforcement an increase in hardness is bserved.

A major challenge in processing such reinforced coatings is nhomogeneous mixing of MWCNT with the matrix phase.MWCNT has high surface energy and they tend to agglomerate in powder. Poor dispersion centres, i.e., agglomerated chunks MWCNT in the coating raises the stress concentration levels when coated component is subjected to forces and exacerbatethe properties.9 Inhomogeneous dispersion also results in weak nchoring between the splats.

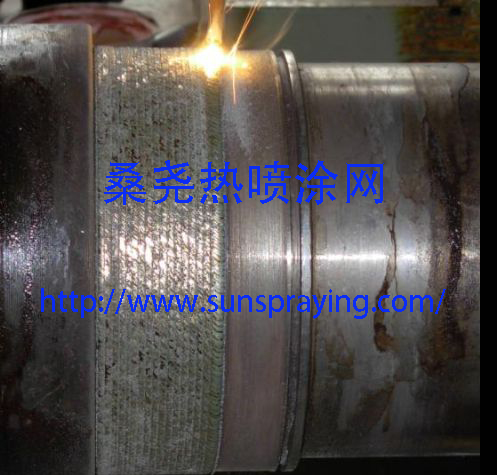

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|