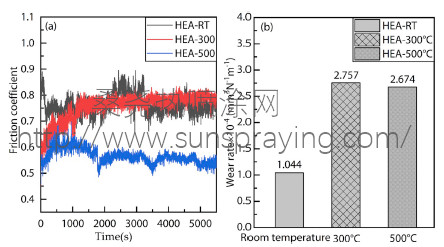

It was reported that Al promotes the BCC-type phase in as-cast CoCrFeNiTiAlx alloys. With the addition of Al, ordered BCC-type phase, which was ascertained as NiAl-based intermetallic phase, increased gradually. The brittle NiAl-based intermetallic phase is detrimental to wear resistance. Therefore, in the present study, a lower Al content high entropy alloy coating, Al0.6TiCrFeCoNi high entropy alloy coating, was produced using HVOF. It was characterized in terms of microstructure, phase composition and hardness. The wear behavior against Al2O3 counter body was investigated at room temperature, T=300°C and T=500°C and the wear mechanisms at different temperatures were discussed. An Al0.6TiCrFeCoNi high entropy alloy coating was produced by high-velocity-oxygen-fuel spraying. The microstructure and phase composition of the coating were investigated, moreover the hardness and the fracture toughness of the coating were determined. The wear behavior of the coating at different temperatures was evaluated using a pin-on-disc test. The results show that the coating was very dense and consisted of lamellae. Two BCC phases with similar lattice parameters were detected in the as-sprayed coating. The wear of the coating against an Al2O3 counter body was mainly caused by abrasion at all temperatures. The role of fatigue wear increased with increasing test temperature. In addition, tribo-reaction played an important role at the test temperature of T=500°C, which led to the lowest friction coefficient of the coating under the given test conditions.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|