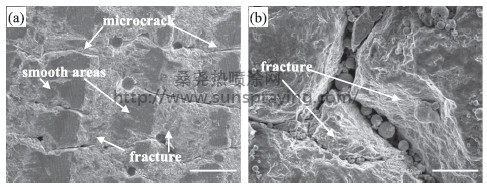

Many researchers have focused on the plasma-sprayed Al2O3-13%TiO2 coatings and the effect of laser remelting on tribological property. Wang et al. reported that the laser remelting of plasma-sprayed Al2O3-13%TiO2 coatings on the Ti-6Al-4V alloy. It was shown that the laser remelting can be employed for the fabrication of dense Al2O3-13%TiO2 coatings and improve the hardness. Dubourg et al. studied properties of Al2O3–13%TiO2 coatings prepared by laser-assisted air plasma spraying and results showed that laser assistance may improve the microstructural and mechanical properties. Li et al. discussed the effects of feedstock preparation, plasma spraying and laser remelting process on the microstructure of the laserremelted Al2O3-13 wt%TiO2 coatings. Gao et al.indicated the interface characteristics of Al2O3–13%TiO2 ceramic coatings prepared by laser cladding and found that a two-layer substructure composed of fully melted layer and liquid-phase sintered layer exists in the ceramic coating. However, still now, few investigations were done on Al2O3-40%TiO2 coatings and whether the laser remelting can provide good tribological property should be studied further. The Al2O3-40%TiO2 oating fabricated by plasma spraying on carbon steel substrate were remelted by laser, and the effect of laser remelting on microstructure and wear resistance of plasma sprayed Al2O3-40%TiO2 coating were studied. The microstructure and phase composition of plasma sprayed and laser remelted coatings were analyzed using scanning election microscopy (SEM), energy disperse spectroscopy (EDS) and X-ray diffraction (XRD). The micro-hardness and adhesion strength of two coatings were measured using micro-hardness tester and electronic universal tensile testing machine. The wear resistance of two coatings was tested through a slurry rubber wheel abrasion test machine, and the wear behaviour was also studied by SEM. The results show that metastable phase γ-Al2O3 in coating is completely transformed into stable phase α- Al2O3 after laser remelting. The laser remelted coating becomes much denser, and then its microhardness and adhesion strength have been greatly improved. The laser remelted coating exhibits better wear resistance compared to the plasma-sprayed coating, and the main wear mechanism responsible for wear was microcrack and fracture wear.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|