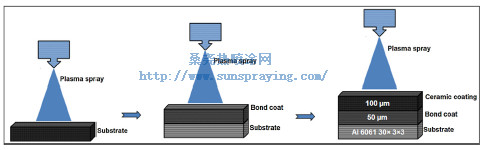

Aluminium alloys offer a wide range of desirable properties and find applications in the fabrication of engineering structures. The 6000 series aluminium alloys are utilized in the production of cylinder blocks, crankcases and pistons as considerable amount of weight savings can be effected. Especially,Al6061 alloy possesses many favourable characteristics like heat-treatability, good toughness, corrosion resistance along with mechanical strength which make it suitable to cater medium and high strength structural applications. The internal combustion (IC) engine components such as piston and cylinder liner are generally produced using steel, cast iron, and aluminium alloys. These parts experience wear regularly due to friction as they involve continuous movements during IC engine operations. Moreover, these components require hard exterior structure to endure wear and soft interior to absorb energy. Hence, various types of coating materials are attempted on IC engine components to get high hardness and wear resistance thereby longer operating life. Among various coatings, ceramic coatings are normally preferred for wear resistant and thermal load bearing characteristics. tIn the present research work, various ceramic materials such as Al2O3- Cr2O3- SiC, andAl2O3- ZrO2- TiO2were developed for the analysis of wear performance and hardness. The specimens were coated using plasma spray coating technique. A bond coat of 50m thickness was applied on the substrate using NiCrAlY for good adhesion before laying thetop coat. The wear behaviour and hardness of the samples were investigated by wear and hardness tests. The Energy Dispersive X-ray Analysis (EDAX) was performed to analyse the chemical composition of the samples. The Field Emission Scanning Electron Microscope(FE-SEM) was used to analyse the surface and cross-section of the samples. X-ray diffraction(XRD) studies are carried out to understand the structural and crystallographic information. The performances of the coated and uncoated samples were compared and investigated. It was observed that the specimen with Al2O3(60%) + ZrO2(20%) + TiO2(20%) coating produced best results for wear rate (0.03612 mm3/Nm) and Coefficient of friction (0.357) . The proposed ceramic coating composition could be recommended for automobile components that require good wear and heat resistance to improve the service life.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|