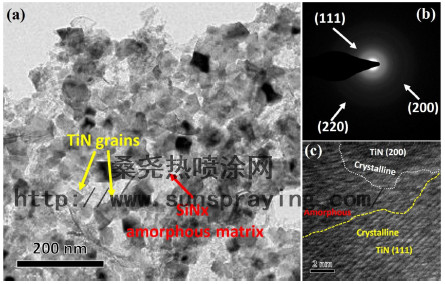

Despite the appropriate properties of the CAE-synthesized coatings, relatively poor adhesion to substrate affects their tribological properties and decreases the wear resistance of the coated substrates considerably. Furthermore, due to the columnar structure of these coatings, they cannot provide adequate corrosion protection. Hence, tremendous studies have been carried out to overcome these drawbacks. To enhance the adhesion properties of TiSiN coating, Komarov et al. deposited this coating onto nitro-carburized 12×18H10T steel substrates via reactive magnetron sputtering method. Based on their findings, the nitro-carburizing process of 12×18H10T steel leads to increase its surface hardness which subsequently enhances the adhesion of the coating. In another study, Yang et al., deposited multilayer TiSiN/CrN coatings using CAE process on SKH-51 steel. They reported that the multilayer structure of TiSiN/CrN coating can 77% reduce the residual stress compared to single-layer TiSiN coating. Moreover, it was found that the multilayer TiSiN/CrN film has superior resistance to plastic deformation compared to the monolayer TiSiN coating. In another work, Chang et al., synthesized multilayer TiVN/TiSiN films via CAE method on WCeCo substrates. They found that the multilayer TiVN/TiSiN coating has greater hardness values and better tribological performance than those of the single-layer TiSiN and also TiVN coatings. Furthermore, they claimed that higher hardness and lower adhesive build-up-edge tendency of the multilayer TiVN/TiSiN films might enhance the total resistance to wear and appropriateness of these films for machining applications. Chang et al, also investigated the properties of Ti/TiN/TiSiN/ TiSiCN coating deposited by CAE method on WCeCo substrates. They found that the multilayered architecture remarkably enhances the adhesion strength between the TiSiCN top layer and WCeCo substrate for corrosion protection purposes. Wan et al., deposited TiN/Ti and TiSiN/Ti coating onto 304 stainless steel substrates. Their findings represented that the TiSiN/Ti layer has a denser structure with smaller grains compared to the TiN/Ti coating. Also, it was found that the higher resistance to corrosion of TiSiN/Ti layer in comparison with TiN/Ti coating is related to Si doping which leads to the creation of a nanocomposite microstructure with a lower amount of grain boundaries. In another study, Ahmed et al, deposited a multilayered Ti/TiN/TiSiN on AISI M42 tool steel. They observed that corrosion pitting is predominant in the TiSiN films deposited on steel, which arises from surface imperfections such as pinholes.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|