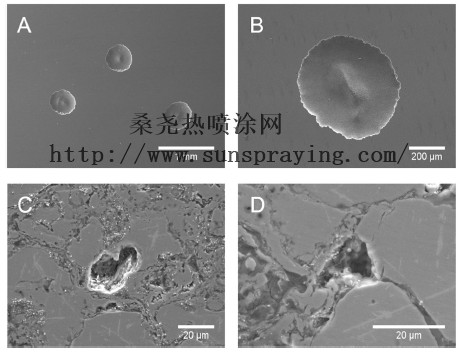

Even though the FeCrMnCoSi HVOF coatings are highly resistant against cavitation erosion, pitting corrosion caused by chlorides represents an inherent risk associated with marine applications and, therefore, any protective coating must also possess a satisfactory corrosion resistance. To date, however, the corrosion properties of FeCrMnCoSi alloys and coatings are scarce in the literature. Most available studies have evaluated the corrosion performance of austenitic FeCr-based alloys in which the austenite is stabilized by Mn, N, and C additions. Electrochemical results indicated that Fe18Cr10MnNC alloys are highly resistant to corrosion in chloride-rich media (NaCl solution 1 M). The formation of a passivating layer with outstanding stability in presence of chlorides was attributed mainly to the N and C additions, which are beneficial to increase both the thickness and the Cr content of the passive film. However, Mn additions have been found to be deleterious regarding the resistance against localized corrosion for some FeCr-based alloys due to the enrichment of Mn and the increase of the point defect density in the protective film. As a result, the dissolution rate of the alloyed Mn steels inside the pit cavity is increased, which retards the repassivation process. These controversial results point out that, besides the Cr and Mn content, other alloying elements such as N, C, Co, and Si are determinant for the corrosion resistance of Mn-containing austenitic stainless steels. FeCrMnCoSi coating (so-called CaviTec alloy) is recognized as an efficient protective measure to extend the service-life of steel components subjected to severe cavitation erosion. Besides this requirement, many applications also demand coatings with proper corrosion and wear resistances. The aim of this study is to evaluate the pitting corrosion and the sliding wear resistances of CaviTec coatings produced by high-velocity oxygen fuel (HVOF) and deposited onto a 304 stainless steel (SS). The corrosion performances in simulated seawater indicated that these coatings exhibit satisfactory corrosion resistance with regions around the inter-splats representing the preferential weak links sites for pitting corrosion initiation. CaviTec coating wear is characterized by mild delamination followed by severe abrasive wear once the hard-martensitic debris are added in the tribosystem due to the transformation induced plasticity (TRIP) effect. Corrosion and wear results point out that the CaviTec coatings, originally developed to possess high cavitation erosion resistance, also present satisfactory corrosion resistance in seawater-like medium and interesting dry sliding wear performance, which can extend their application domain.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|